10

1. Safety precautions

▶ Before installing the unit, make sure you read all the “Safety Precautions”.

▶ The “Safety Precautions” provide very important points regarding safety. Make sure you follow them.

▶ Please report to or take consent by the supply authority before connection to the system.

MEANINGS OF SYMBOLS ON THE UNIT

WARNING

(Risk of re)

This symbol is only for R32 refrigerant. The type of the refrigerant used is written on the nameplate on the outdoor unit.

R32 refrigerant is ammable. If the refrigerant leaks, or comes in contact with re or parts that generate heat, it may create harmful gas

and pose a risk of re.

Read the OPERATION MANUAL carefully before operation.

Service personnel are required to carefully read the OPERATION MANUAL and INSTALLATION MANUAL before operation.

Further information is available in the OPERATION MANUAL, INSTALLATION MANUAL, and the like.

• Please report to or take consent by the supply authority before connection

to the system.

• Be sure to read “Safety precautions” before installing the air conditioner.

• Be sure to observe the cautions specied here as they include important

items related to safety.

• The indications and meanings are as follows.

Warning:

Could lead to death, serious injury, etc.

Caution:

Could lead to serious injury in particular environments when operated

incorrectly.

• After reading this manual, be sure to keep it together with the instruction

manual in a handy place on the customer’s site.

Symbols put on the unit

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Indicates that caution should be taken with rotating parts.

: Indicates that the main switch must be turned off before servicing.

: Beware of electric shock.

: Beware of hot surface.

Warning:

Carefully read the labels afxed to the main unit.

Warning:

• Do not use refrigerant other than the type indicated in the manuals

provided with the unit and on the nameplate.

- Doing so may cause the unit or pipes to burst, or result in explosion or re

during use, during repair, or at the time of disposal of the unit.

- It may also be in violation of applicable laws.

- MITSUBISHI ELECTRIC CORPORATION cannot be held responsible for

malfunctions or accidents resulting from the use of the wrong type of

refrigerant.

• When handling this product, always wear protective equipment.

EG: Gloves, full arm protection namely boiler suit, and safety glasses.

- Improper handling may result in injury.

• Do not install it by yourself (customer).

Incomplete installation could cause injury due to re, electric shock, the

unit falling or leakage of water. Consult the dealer from whom you

purchased the unit or special installer.

• Install the unit securely in a place which can bear the weight of the unit.

When installed in an insufcient strong place, the unit could fall causing

injured.

• Use the specied wires to connect the indoor and outdoor units securely

and attach the wires rmly to the terminal board connecting sections so

the stress of the wires is not applied to the sections.

Incomplete connecting and xing could cause re.

• Do not use intermediate connection of the power cord or the extension

cord and do not connect many devices to one AC outlet.

It could cause a re or an electric shock due to defective contact, defective

insulation, exceeding the permissible current, etc.

• Check that the refrigerant gas does not leak after installation has

completed.

• Perform the installation securely referring to the installation manual.

Incomplete installation could cause a personal injury due to re, electric

shock, the unit falling or leakage of water.

• Perform electrical work according to the installation manual and be sure to

use an exclusive circuit.

If the capacity of the power circuit is insufcient or there is incomplete

electrical work, it could result in a re or an electric shock.

• Attach the electrical part cover to the indoor unit and the service panel to

the outdoor unit securely.

If the electrical part cover in the indoor unit and/or the service panel in the

outdoor unit are not attached securely, it could result in a re or an electric

shock due to dust, water, etc.

• Be sure to use the part provided or specied parts for the installation work.

The use of defective parts could cause an injury or leakage of water due to

a re, an electric shock, the unit falling, etc.

• Ventilate the room if refrigerant leaks during operation.

If the refrigerant comes in contact with a ame, poisonous gases will be

released.

• If the supply cord is damaged, it must be replaced by the manufacturer, its

service agent or similarly qualied persons in order to avoid a hazard.

• This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the

appliance.

• The installer and system specialist shall secure safety against leakage

according to local regulation or standards.

- The instructions in this manual may be applicable if local regulation are not

available.

• Pay a special attention to the place, such as a basement, etc. where

refrigeration gas can stay, since refrigeration is heavier than the air.

• This appliance is intended to be used by expert or trained users in shops,

in light industry and on farms, or for commercial use by lay persons.

• When installing, relocating, or servicing the air conditioner, use only the

specied refrigerant written on the outdoor unit to charge the refrigerant

lines. Do not mix the refrigerant with any other refrigerant, and do not allow

air to remain in the lines.

- If air is mixed with the refrigerant, then it may cause abnormal high pressure in

the refrigerant lines, resulting in an explosion and other hazards.

- The use of any refrigerant other than that specied for the system will cause

mechanical failure, system malfunction, or unit breakdown. In the worst case,

this could lead to a serious impediment to securing product safety.

- It may also be in violation of applicable laws.

- MITSUBISHI ELECTRIC CORPORATION cannot be held responsible for

malfunctions or accidents resulting from the use of the wrong type of refrigerant.

Contents

1. Safety precautions ........................................................................................10

2. Selecting the installation location .................................................................12

3. Selecting an installation site & Accessories.................................................. 12

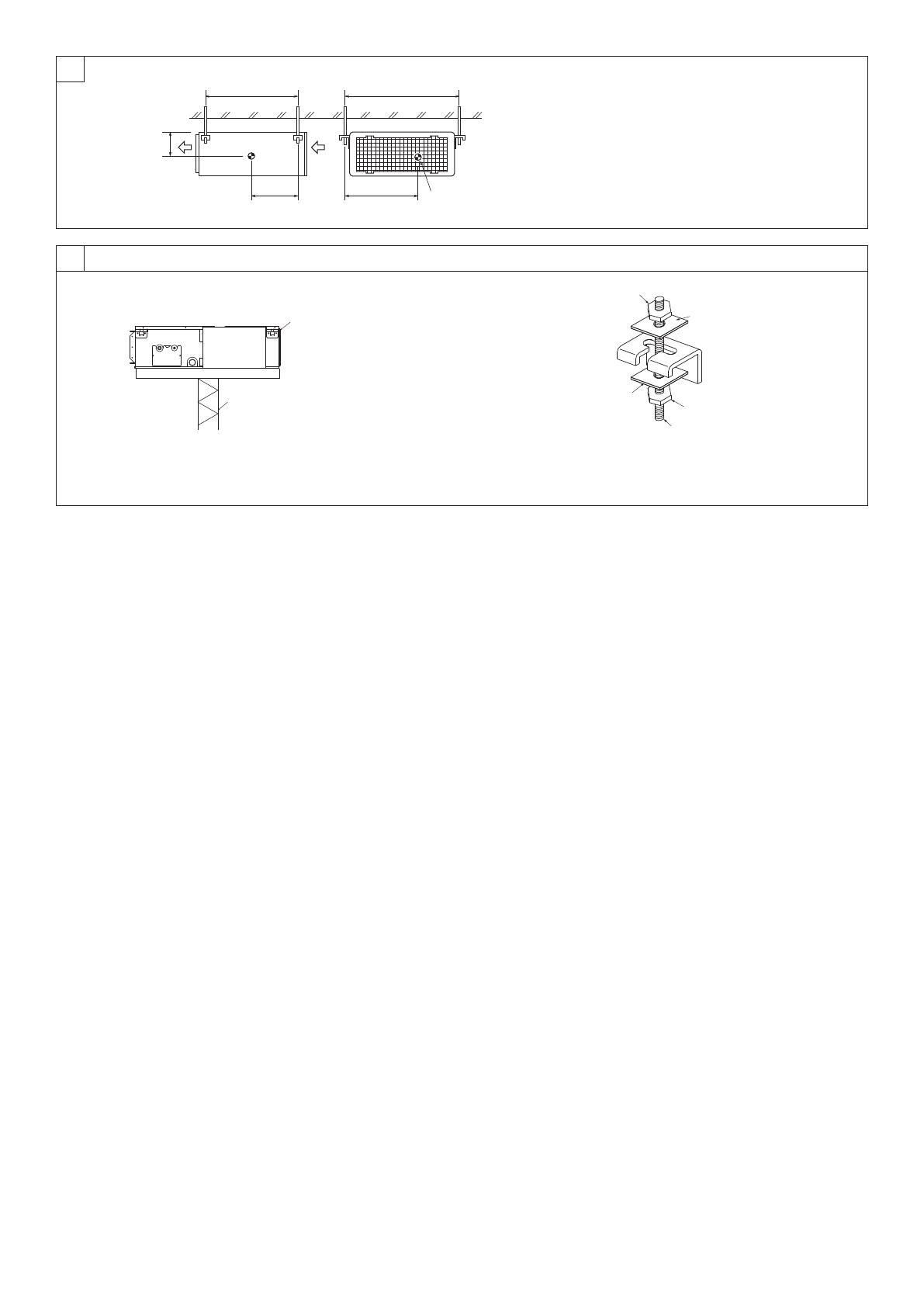

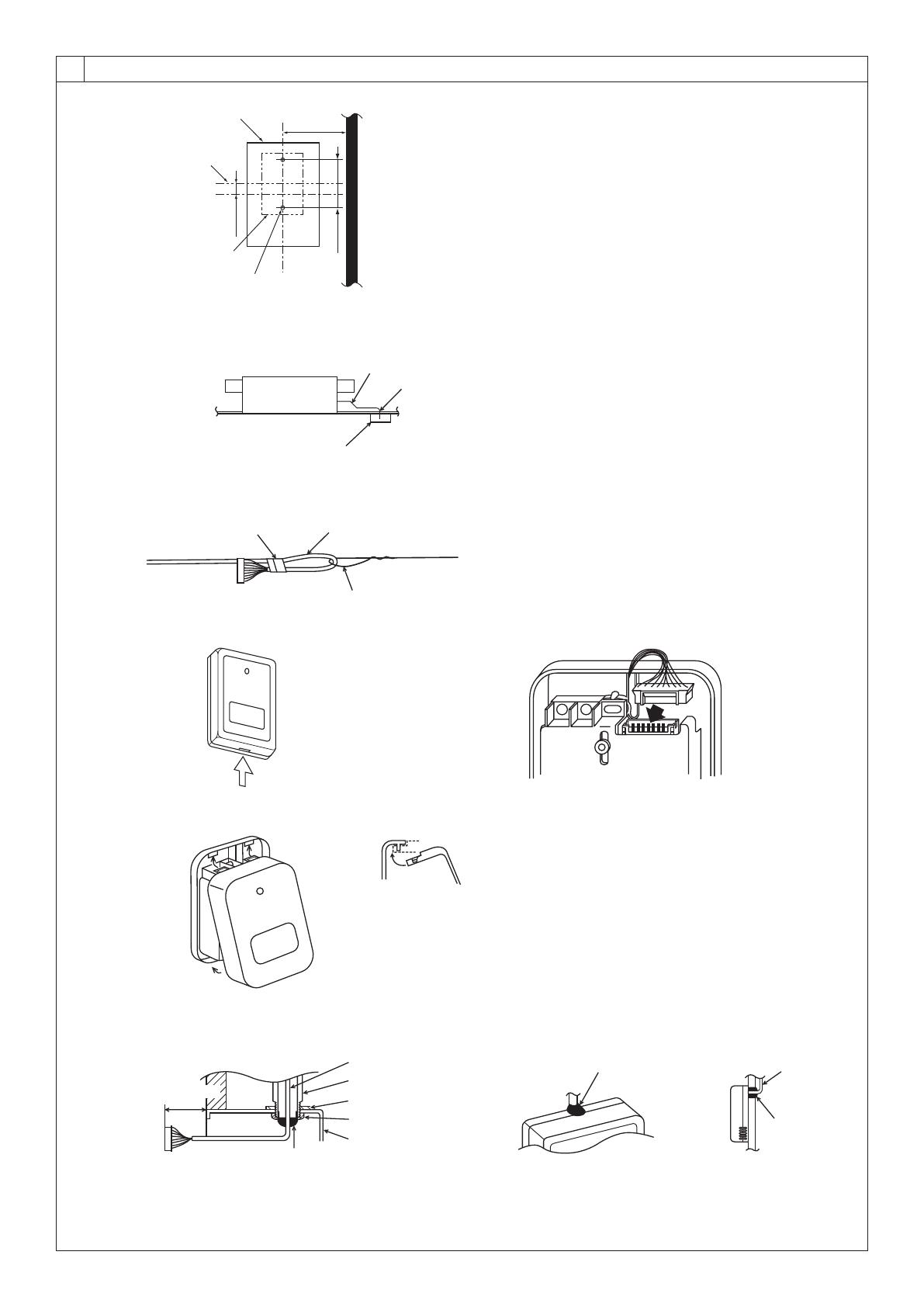

4. Fixing hanging bolts......................................................................................13

5. Installing the unit...........................................................................................13

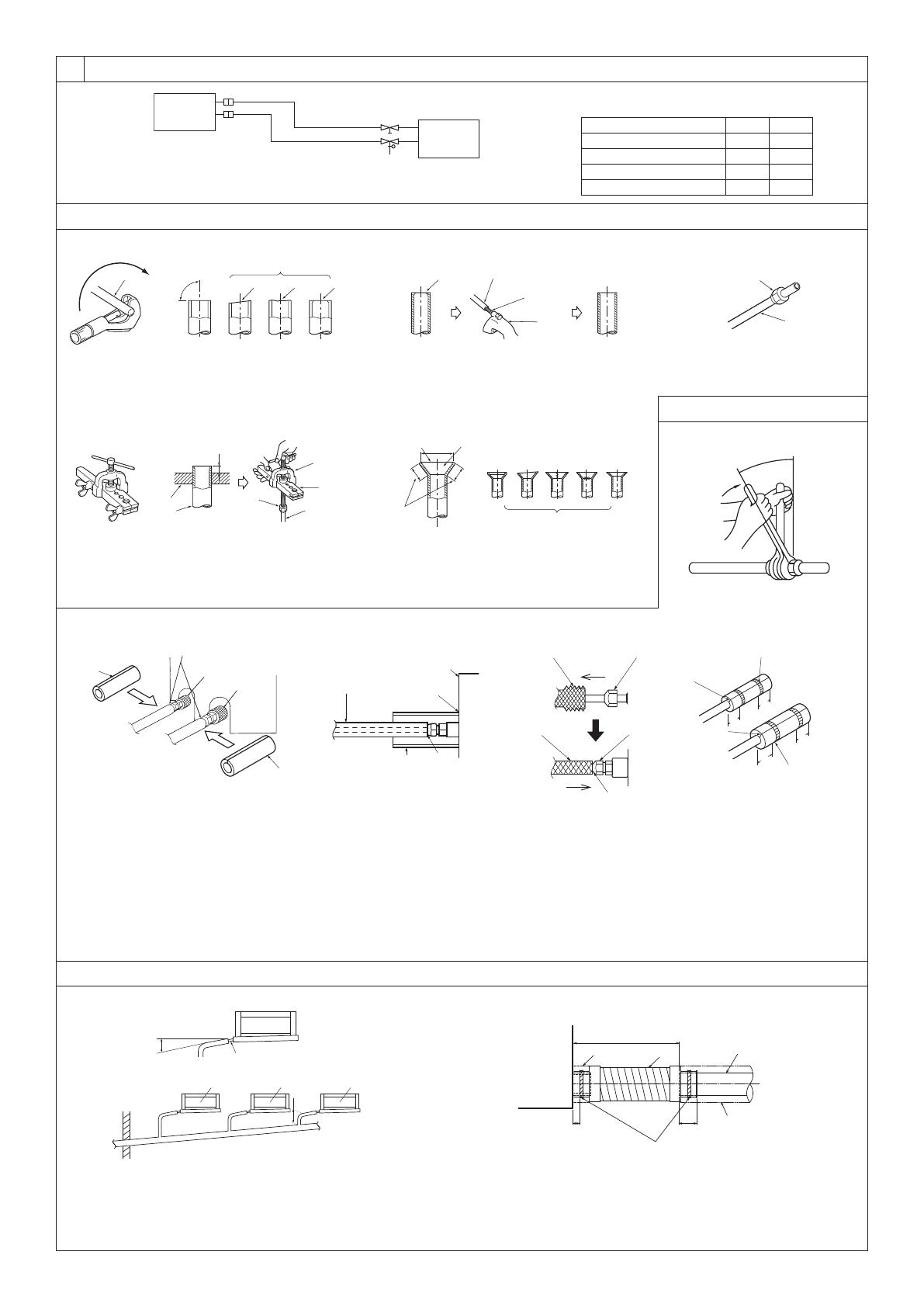

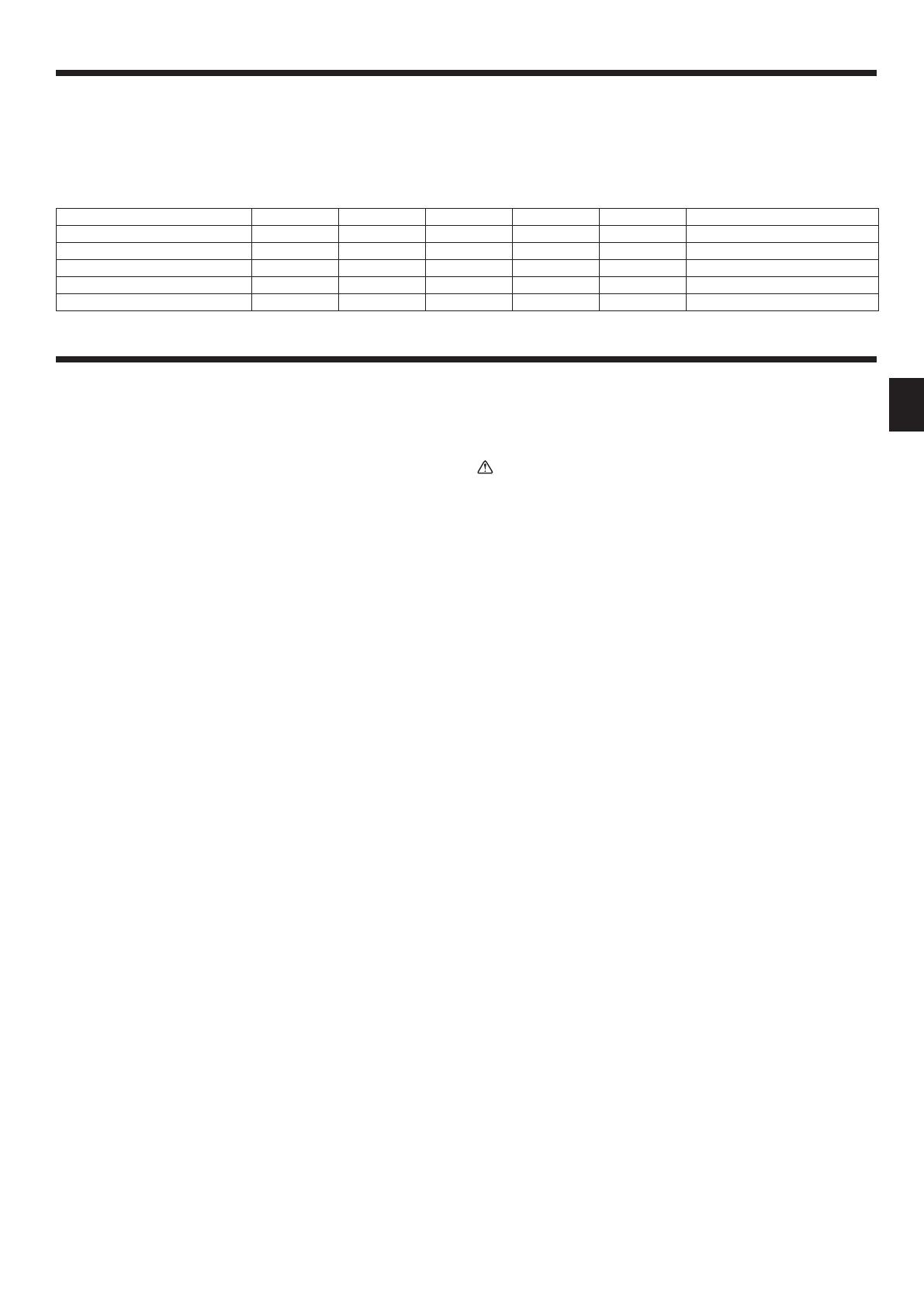

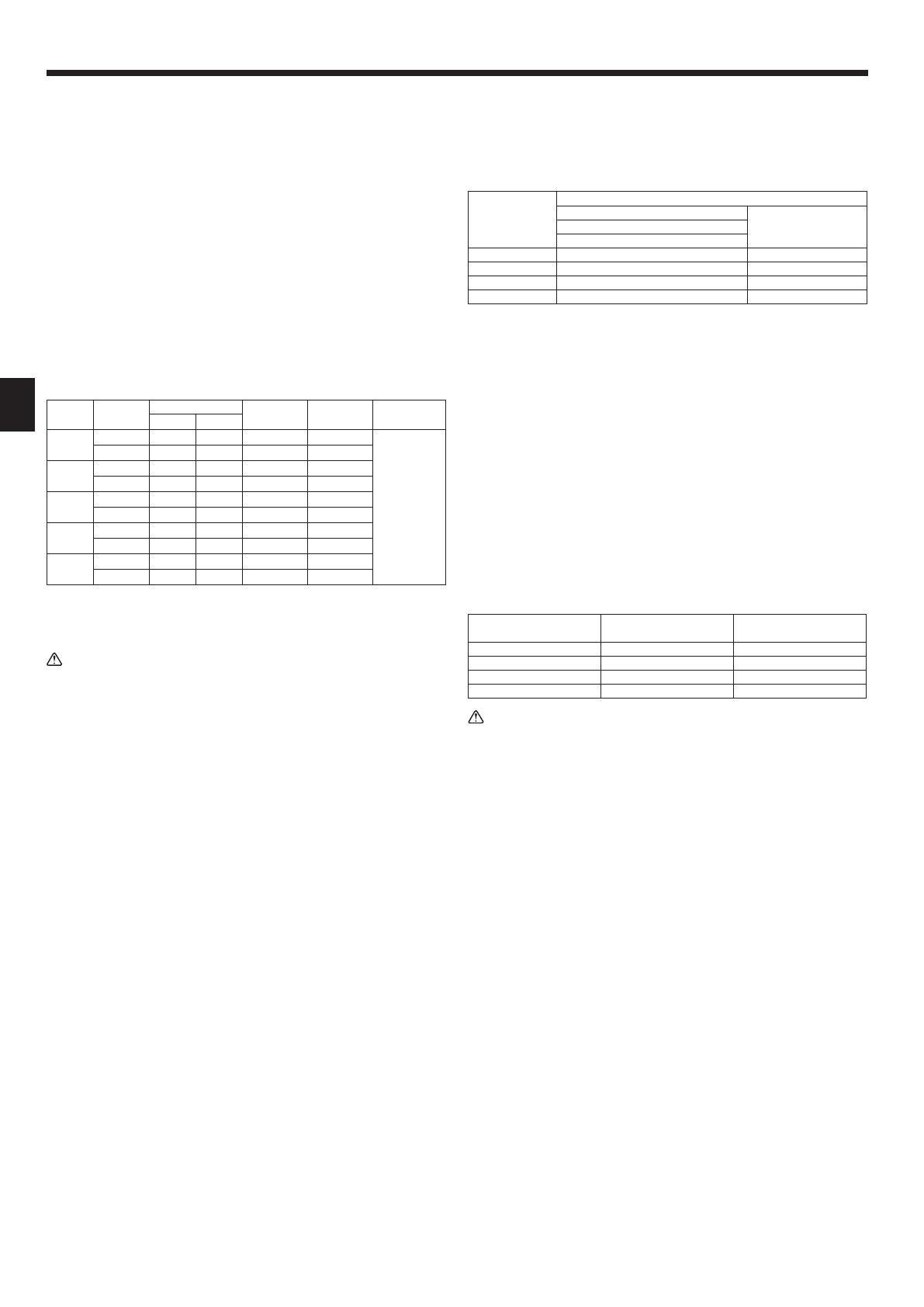

6. Refrigerant piping work.................................................................................14

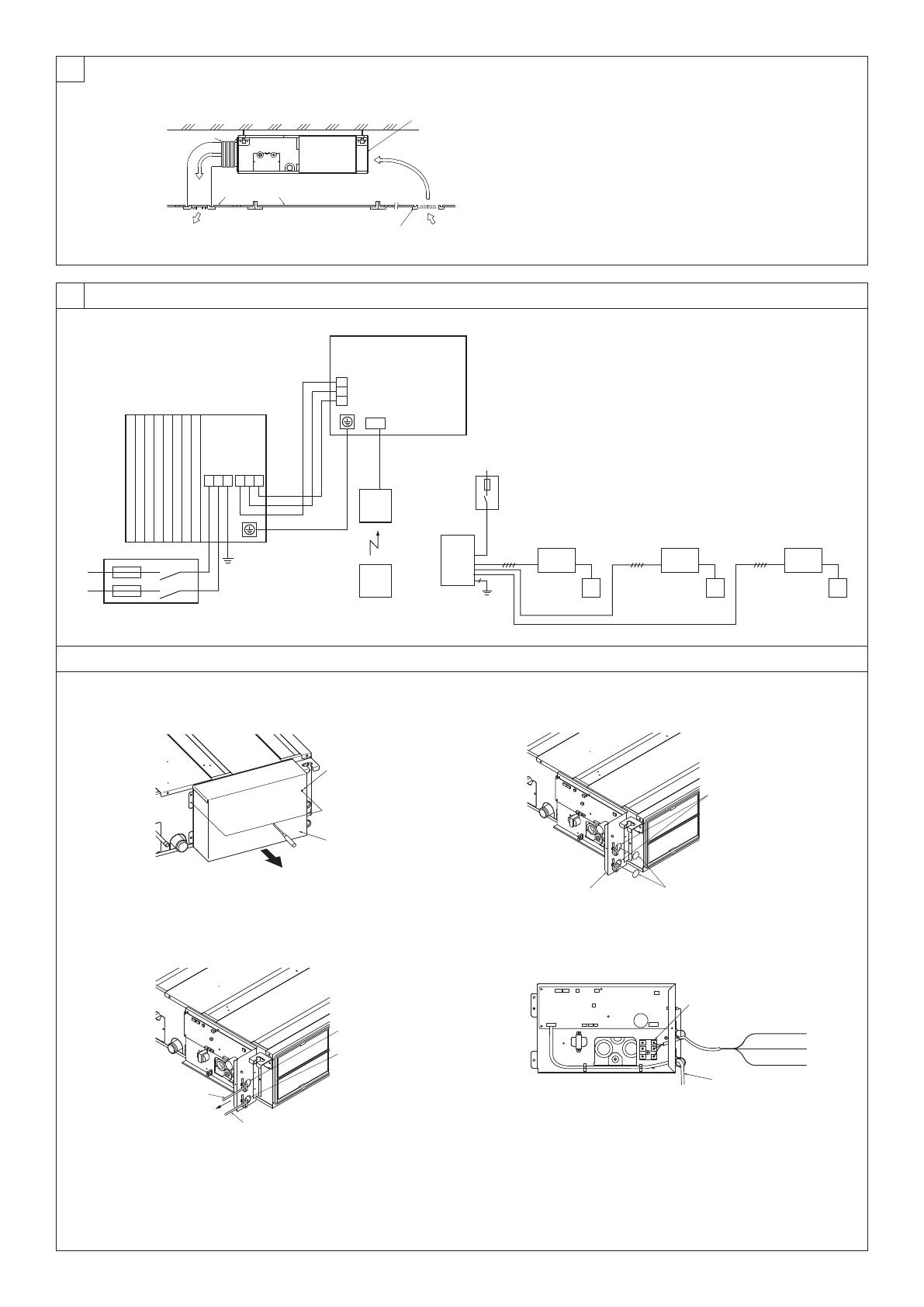

7. Duct work......................................................................................................15

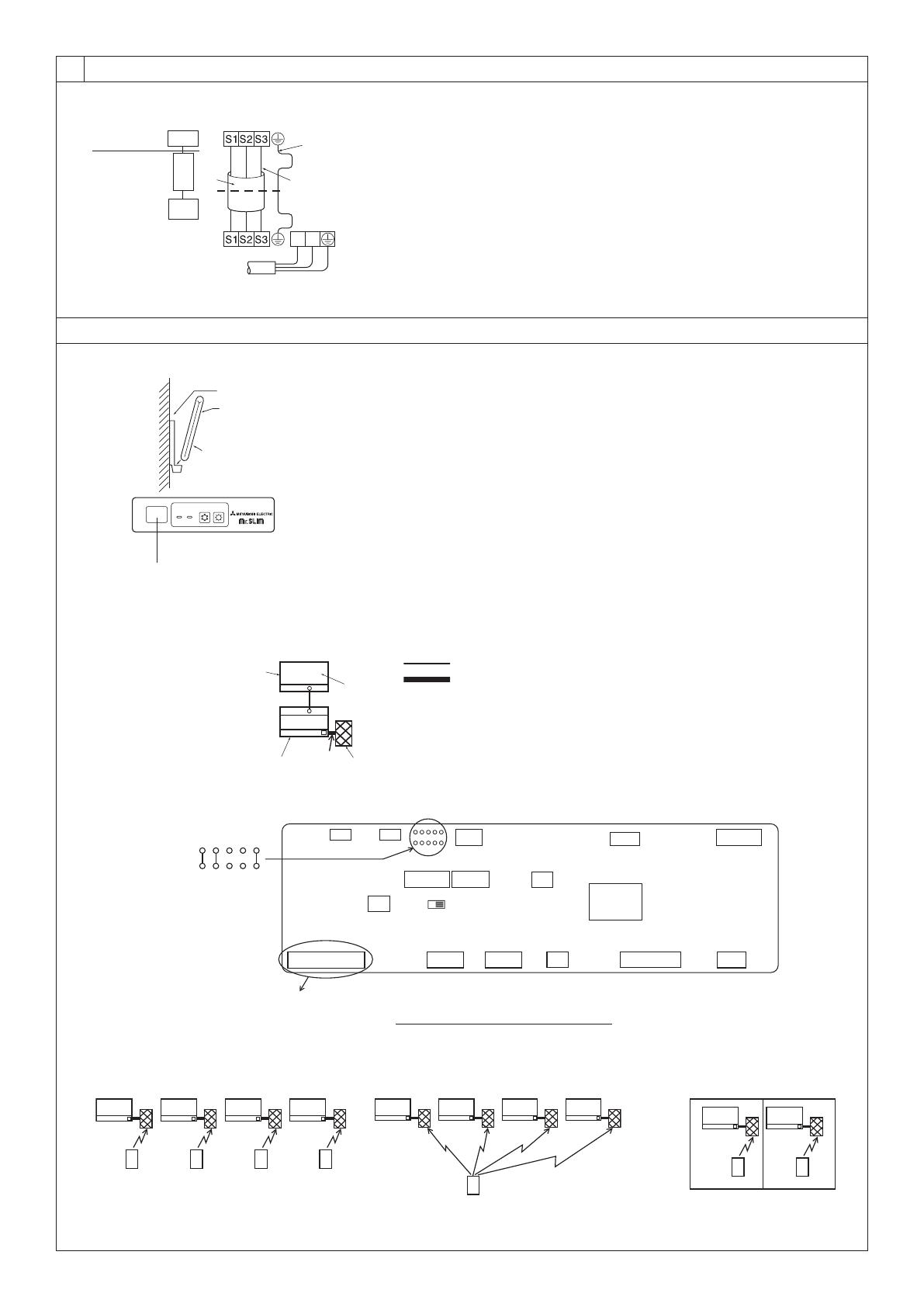

8. Electrical work ..............................................................................................16

9. Test run .........................................................................................................18

10. Maintenance ............................................................................................... 20

This Installation Manual describes only for the indoor unit and the connected

outdoor unit of SUZ series.

If the connected outdoor unit is MXZ series, refer to the Installation Manual for

MXZ series.