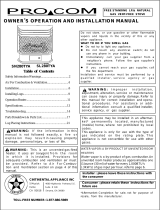

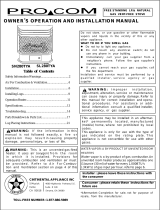

Procom AL500HYLA is a 50,000 BTU/Hr manually controlled outdoor gas fireplace. It is designed for use with propane gas only and features a piezo ignition system for easy lighting. The fireplace includes a set of 10 logs that are designed to provide a realistic flame effect. The Procom AL500HYLA is also equipped with a safety pilot system that shuts off the gas supply if the flame is extinguished by rough wind. This fireplace is a great way to add warmth and ambiance to your outdoor space.

Here are some of the key features and benefits of the Procom AL500HYLA:

- 50,000 BTU/Hr heating capacity

Procom AL500HYLA is a 50,000 BTU/Hr manually controlled outdoor gas fireplace. It is designed for use with propane gas only and features a piezo ignition system for easy lighting. The fireplace includes a set of 10 logs that are designed to provide a realistic flame effect. The Procom AL500HYLA is also equipped with a safety pilot system that shuts off the gas supply if the flame is extinguished by rough wind. This fireplace is a great way to add warmth and ambiance to your outdoor space.

Here are some of the key features and benefits of the Procom AL500HYLA:

- 50,000 BTU/Hr heating capacity

-

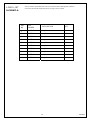

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

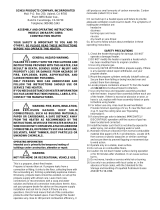

Procom AL500HYLA is a 50,000 BTU/Hr manually controlled outdoor gas fireplace. It is designed for use with propane gas only and features a piezo ignition system for easy lighting. The fireplace includes a set of 10 logs that are designed to provide a realistic flame effect. The Procom AL500HYLA is also equipped with a safety pilot system that shuts off the gas supply if the flame is extinguished by rough wind. This fireplace is a great way to add warmth and ambiance to your outdoor space.

Here are some of the key features and benefits of the Procom AL500HYLA:

- 50,000 BTU/Hr heating capacity

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Procom PL600HYLA User manual

-

Procom PCD18T Installation guide

-

Procom PCSD25T Installation guide

-

Procom PCFD32RT-M-U Operating instructions

-

ProCom Heating SN280TYA User manual

ProCom Heating SN280TYA User manual

-

Procom SSU320RHL-G User manual

-

ProCom Heating SN400TYLA User manual

ProCom Heating SN400TYLA User manual

-

Procom ML100TBAHR User manual

-

ProCom Heating EDP200T-O User manual

ProCom Heating EDP200T-O User manual

-

Procom WZL18HLA Installation guide

Other documents

-

ProCom Heating AL500HYLA User manual

ProCom Heating AL500HYLA User manual

-

Thermablaster RE5000FS User manual

Thermablaster RE5000FS User manual

-

Mellerware Quantum 35420 User manual

-

Scheu Products Company 100-RA (1990+) Owner's manual

Scheu Products Company 100-RA (1990+) Owner's manual

-

ProCom Heating ETF200TCC User manual

ProCom Heating ETF200TCC User manual

-

ProCom Heating QN300TYLA User manual

ProCom Heating QN300TYLA User manual

-

ProCom Heating VF18NV-1 User manual

ProCom Heating VF18NV-1 User manual

-

ProCom Heating 210009 User manual

ProCom Heating 210009 User manual

-

Duluth Forge DF450SS-G-RBLK Installation guide

-

ProCom Heating VF18NA-1 Owner's manual