8

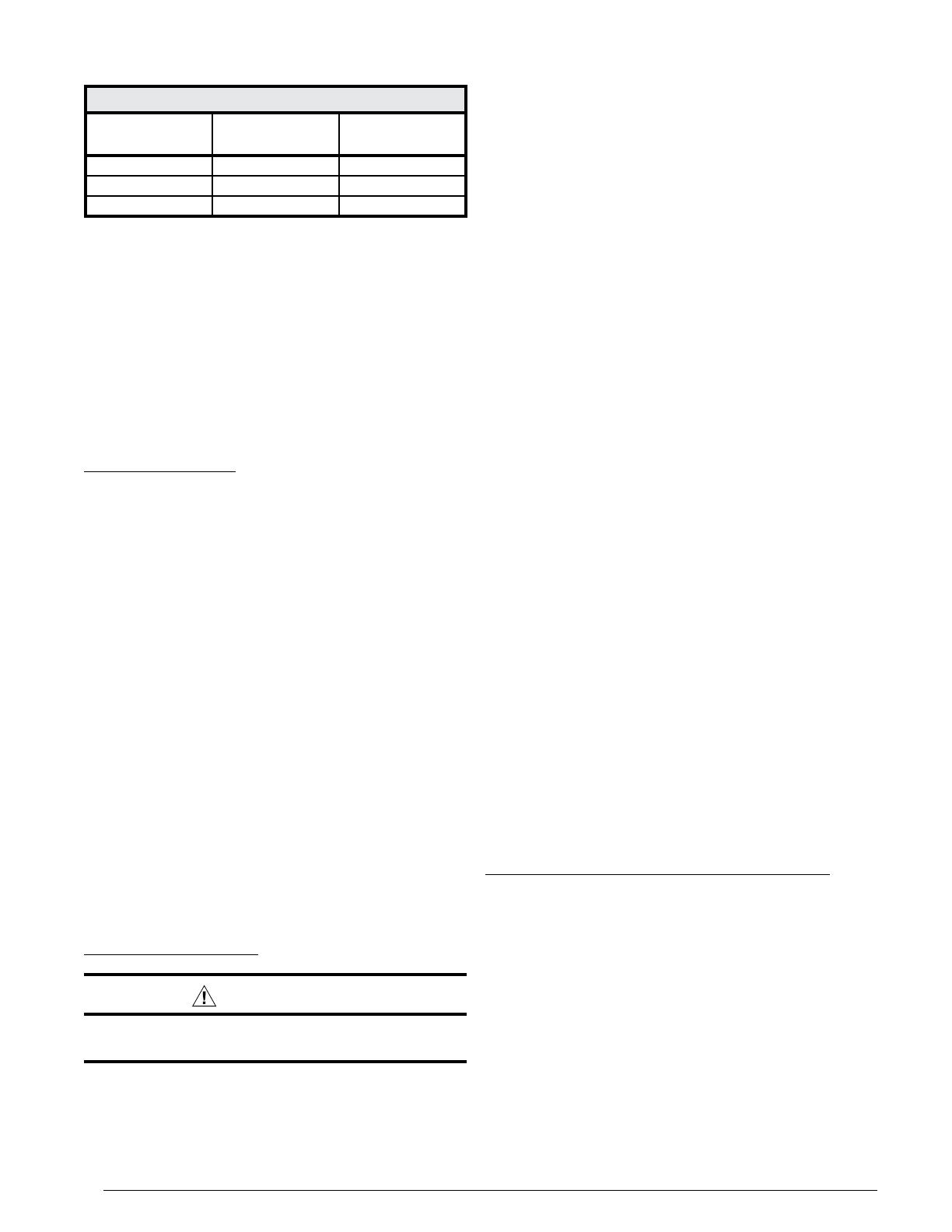

MAXIMUM DIRECT VENT, DUAL PIPE LENGTH (FT.)

M7RL INPUTS

(BTU)

INLET / OUTLET

2” DIAMETER

INLET / OUTLET

3” DIAMETER

45,000 30 60

60,000 30 60

72,000 30 60

†

NOTES:

1. Subtract2.5ft.foreachadditional2inchlongradiuselbow,subtract

5ftforeachadditional2”shortradiiouselbow,subtract3.5ft.foreach

additional3inchlongradiuselbow,and7ft.foreachadditional3

inchshortradiuselbow.

2. Two45degreeelbowsareequivalenttoone90degreeelbow.

3. Thistableappliesforelevationsfromsealevelto2,000ft.Forhigher

elevations,decreasepipelengthsby8%per1,000ftofaltitude.

Table 2. Vent Pipe Lengths

• In the absence of local codes, the location of any

combustionairinletrelativetoanyventterminalmust

beatleast8inches.Thisincludesinstallationsinvolving

morethanonefurnace.

• Thequalityofoutdoorairmustalsobeconsidered.Be

surethatthecombustionairintakeisnotlocatednear

a source of solvent fumes or other chemicals which

cancausecorrosionofthefurnacecombustionsystem.

(Seepage5forasamplelistofsubstances).

• Routepipingasdirectaspossiblebetweenthefurnace

and the outdoors. Longer vent runs require larger

diameters.Ventpipingmustbeslopedupwards1/4”

perfootinthedirectionfromthefurnacetotheterminal.

This ensures that any condensate ows back to the

condensatedisposalsystem.

• When a 2-pipe system is used, the combustion air

intake and the vent exhaust must be located in the

same atmospheric pressure zone. This means both

pipesmustexitthebuildingthroughthesameportion

ofexteriorwallorroofasshowninFigure1,Figure2

&Figure4(page9)andFigure29(page38).

• Pipingmustbemechanicallysupportedsothatitsweight

doesnotbearonthefurnace.Pipesupportsmustbe

installedaminimumofeveryvefeetalongtheventrunto

ensurenodisplacementafterinstallation.Supportsmay

beatshorterintervalsifnecessarytoensurethatthere

arenosaggingsectionsthatcantrapcondensate.Itis

recommendedtoinstallcouplings(Figure29)alongthe

ventpipe,oneithersideoftheexteriorwall.Couplings

mayberequiredbylocalcode.

• Ifbreakableconnectionsarerequiredinthecombustion

airinletpipe(ifpresent)andexhaustventpiping,then

straight neoprene couplings for 3” piping with hose

clampscanbeused.Thesecouplingscanbeordered

through your local furnace distributor. To install a

coupling:

1. Slidetherubbercouplingovertheendofthepipe

thatisattachedtothefurnaceandsecureitwithone

ofthehoseclamps.

2. Slidetheotherendoftherubbercouplingontothe

otherpipefromthevent.

3. Securethecouplingwiththesecondhoseclamp,

ensuringthattheconnectionistightandleakfree.

OutdoorTerminations-HorizontalVenting

• Ventandcombustionairintaketerminationsshallbe

installedasshown inFigure1,Figure 2,Figure3,&

Figure4andinaccordancewiththeseinstructions:

• Ventterminationclearancesmustbeconsistentwiththe

NFGC,ANSI2223.1/NFPA54and/ortheCSAB149.1,

NaturalGasandPropaneInstallationCode.Table14,

(page37)liststhenecessarydistancesfromthevent

terminationtowindowsandbuildingairintakes.

• Vent and combustion air intake terminations must

be located to ensure proper furnace operation and

conformance to applicable codes. A vent terminal

mustbelocatedat least3feetaboveanyforcedair

inletlocatedwithin10feet.Thisdoesnotapplytothe

combustionairinletofadirectvent(twopipe)appliance.

InCanada,CSAB149.1takesprecedenceoverthese

instructions.SeeTable14.

Condensingfurnacecombustionproductshaveverylittle

buoyancy,soTable2istobeusedwithoutconsideration

ofanyverticalriseinthepiping.

VentPipeMaterial

Ventandcombustionairpipeandttingsmustbeone

ofthefollowingmaterialsinthelistandmustconformto

theindicatedANSI/ASTMstandards.

MATERIALS STANDARDS

SCHEDULE40PVC................................................... D1785

PVC-DWV.................................................................. D2665

SDR-21&SDR-26..................................................... D2241

ABS-DWV.................................................................. D2661

SCHEDULE40ABS....................................................F628

FOAM/CELLULARCOREPVC.................................F891

*POLYPRO

®

BYDURAVENT................................. ULC-S636

*WhenusingPolyPro

®

,allventingandttingsmustbefromthesame

manufacturerwithnointerchangingofothermaterials.Refertospecic

instructionssuppliedwiththePolyProventkits.

WhenjoiningPVCtoPVC,usecementthatconformsto

ASTMstandardD2564.PVCprimermustmeetstandard

ASTMF656.WhenjoiningABStoABS,usecementthat

conformstoASTMstandardD2235.WhenjoiningPVCto

ABS,usecementasspeciedinprocedurefromASTM

standardD3138

In Canada, all plastic vent pipes and ttings including

anycement,cleaners,orprimersmustbecertiedasa

systemtoULCS636.Howeverthisrequirementdoesnot

applytothenishangesorpipinginternaltothefurnace.

VentPipeInstallation

CAUTION:

Combustion air must not be drawn from a

corrosive atmosphere.

Thisfurnacehasbeencertiedforinstallationwithzero

clearancebetweenventpipingandcombustiblesurfaces.

However,itisgoodpracticetoallowspaceforconvenience

ininstallationandservice.