6

1. Introduction

1.1 History The development of linear fluorescent goes back to the thirties of the 20th

century. The diameter of 51mm was very voluminous. However, better

efficiency did not come up before the fifties.

The improvements according to the luminous flux and lifetime with the T12

lamp (38 mm diameter) made an economic and even outdoor application

possible. There were continuous improvements for optimizations as for

example Amalgamtechnology. In this term fluorescent lamps were operated

by conventional control gears (CCG).

The decisive breakthrough was at the end of the 70s and early 80s. In the

year 1978, a new T8/∅ 26 mm- lamp generation started to replace

T12/∅38mm- fluorescent lamps. New phosphors with higher resistance

came into the market. Nowadays known under triband-phosphor (LUMILUX

light colours). The diameter of the lamps was reduced from 38mm to 26mm

however the length was kept with 59, 120 and 150 cm as the sockets G13.

The new wattage of 18, 36 and 58 W was advantageous as it was a

reduction of at least 10% compared to the T12/∅38 mm lamps in 20, 40

and 65 W.

This was also the hour of birth for the Electronic Control Gears (ECG). First

the circuits were in a instant start mode what also was called softstart up to

the programmed or preheat start. Together with modern Electronic Control

Gear QUICKTRONIC T8/∅26 mm- fluorescent lamps became even more

efficient and longer lasting. In addition, the thermal behavior of the

luminous flux was improved.

The T8-system was permanently improved as the example of the triband-

phosphor shows with a very high service life of the fluorescent lamp.

In 1995, the next milestone of fluorecent lamp development saw the

introduction of new FH...HE (High Efficiency) systems to the market. With

the reduced diameter of 16 mm only the lamp was designed. It is available

in 14, 21, 28 and 35 W with the G5 sockets. It is 50 mm shorter as the T8

fluorescent lamps.

T5 fluorescent lamps only can be operated by Electronic Control Gear. So

the light output and the life time of the lamp were designed from the

beginning to an optimum of up to 104 lm/W. The maximum luminous flux of

the T5 lamps is at 35 °C compared to 25 °C at T8 or T12 lamps. The

reduced lamp diameter of 16 mm as the maximum lumen output at 35 °C

are the relevant feature for a higher efficiency of the fixture.

1879

Kohlefaden-Glühlampe

von Thomas A. Edison

Incandescent lamps with carbon filament

by Thomas A. Edison

1910

Glühlampen mit Wolfram-Wendel

Incandescent lamps with tungsten coils

1925

BILUX®Zweidraht-Scheinwerferlampen

BILUX®two-wire headlight lamps

1931

Natriumdampf-Niederdrucklampen

Low-pressure sodium vapor lamps

1933

Quecksilberdampf-Hochdrucklampen

High-pressure mercury vapor lamps

1936

Leuchtstofflampen

Fluorescent lamps

1954

XBO Xenon-Hochdruck-

lampen

XBO high-pressure

xenon lamps

1968

VIALOX® NAV Standard

Natriumdampf-Hochdrucklampen

VIALOX®NAV Standard

high-pressure sodium vapor lamps

1968

POWERSTAR HQI

Halogen-Metalldampflampen

POWERSTAR HQI

metal halide lamps

1970

HMI METALLOGEN®Lampen

HMI METALLOGEN®lamps

1971

BILUX®H4

Halogen-Zweidraht-Scheinwerferlampen

BILUX®H4

two-wire halogen headlight lamps for auromobiles

1973

HALOSTAR Niedervolt-Halogenglühlampen

HALOSTAR low-voltage tungsten-halogen lamps

1979

LUMILUX®

Leuchtstofflampen

LUMILUX®

fluorescent lamps

1980

EVG QUICKTRONIC®DE LUXE / ECG

QUICKTRONIC®DE LUXE

1982

OSRAM DULUX®L

Kompakt-Leuchtstofflampen

OSRAM DULUX®L

compact fluorescent lamps

1984

DECOSTAR Niedervolt-Halogenglühlampen

mit Kaltlichtreflektor

DECOSTAR low-voltage tungsten-halogen

lamps with dichroic reflectors

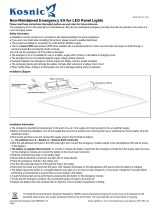

Anwendungsbereich: AC/DC 198 V bis 254 V

Geeignet fr Batteriespannungen 154 V bis 276 V

Zur Verwendung in Anlagen nach VDE 0108 geeignet

Range of application: AC/DC 198 V to 254 V

Range of battery voltage: 154 V to 276 V

Suitable for emergency installations acc. to VDE 0108

Temp.-Test

tc = 70 C max.

class B

0712T201 OW2 Made in Germany

1

L

2

3

4

PL (W)UN (V)fN (Hz)IN (A)lta ( C)

1xL18 W1x16-2050

22050600,090,95 C

2400,0850,93 C OSRAM

1985

OSRAM DULUX®EL Kompaktleuchtstoff-

lampen mit elektronischem Vorschaltgerät

OSRAM DULUX®EL energy-saving lamps

with electronic control gear

1987

POWERSTAR HQI-T

Halogen-Metalldampflampen

POWERSTAR HQI-T

compact metal halide lamps

1991

D1 Gasentladungslampen

D1 gas discharge lamps

1993

COLORSTAR DSX-T 80W

Natrium-Xenonlampen

COLORSTAR DSX-T 80W

sodium xenon lamps

1993

FM Mini-Leuchtstofflampen / FM mini fluorescent

lamps

1995

FH Hocheffiziente Leuchtstofflampen / FH high-

efficient fluorescent lamps

1996

FQ Lichtstarke Leuchtstofflampe / FQ high power

fluorescent lamps

1997

OSRAM ENDURA Die elektrodenlose

Hochleistungsleuchtstofflampe

OSRAM ENDURA The high-performance

electrodeless fluorescent lamp