Page is loading ...

First Sales, LLC

12630 US Highway 33 N

Churubusco, IN 46723

Phone (260) 693-1972 Fax (260) 693-0602

FBW-FBWARS Instruction Manual 170724.docx

FBW Series & FBW ARSENIC Series

Backwashing Filter System

Installation Instructions and Owner’s Manual

1

Pre-installation Instructions

Page 2

Media Types

Page 2

Installation Instructions

Page 5

Timer Operation

Page 8

Maintenance

Page 10

Specifications

Page 12

Component Parts Breakdown

Page 13

Component Parts List

Page 14

Control Valve Breakdown

Page 15

Control Valve Parts List

Page 16

Troubleshooting

Page 17

Control Valve Wiring Diagram

Page 19

Ten Year Limited Warranty

Page 20

Table of Contents

2

Description of the backwashing filter

The FBW system includes a filtration tank (with gravel and distributor) and a backwashing control valve with

bypass. Filtration media for use with the FBW system is purchased separately and selected from the following

types:

PART

MEDIA

VOLUME

PACKAGE

SHIP.

WT.

NUMBER

TYPE / APPLICATION

(CU. FT.)

(LBS.)

A10

ACTIVATED CARBON

TASTE & ODOR REDUCTION

1.00

BAG

29

A05P

0.50

PAIL

14

ACC10

CATALYTIC CARBON

CHLORAMINE REDUCTION

1.00

BAG

29

ACC05P

0.50

PAIL

14

B10

BIRM

REDUCTION OF IRON AND

MANGANESE

1.00

BAG

41

B05P

0.50

PAIL

20

C05P

CALCITE

SELF LIMITING ACID

NEUTRALIZER

0.50

PAIL

45

FA10

FILTER – AG

SUSPENDED SOLIDS

REDUCTION

1.00

BAG

24

FA05P

0.50

PAIL

12

ZEO10

ZEOLITE

SUSPENDED SOLIDS/

SEDIMENT REDUCTION

1.00

BAG

25

Z05P

0.50

PAIL

50

N05

NEUTRALIZER

ACID NEUTRALIZER

0.50

PAIL

43

QFS05P

QUARTZ FILTER SAND

0.50

PAIL

51

(.45mm x .55mm)

SEDIMENT REDUCTION

The FBW ARSENIC system includes a filtration tank (with gravel and distributor), arsenic reduction media

(shipped separately) and a backwashing control valve with bypass. The media is included with the unit for FBW

ARSENIC unit only.

Pre-installation Instructions

3

Successful Application

Any filter media may have specific limitations and/or requirements for successful application. A water sample

should be submitted to First Sales for analysis and recommendation by Customer Service.

FBW ARSENIC IMPORTANT: Contact First Sales technical services to assist with proper

sizing based on the level of arsenic in the water and the flow rate requirement. The arsenic

test results must be from a certified laboratory to ensure accuracy. Other water quality

information is required as well, and will determine if pre-treatment equipment is required to

meet the influent water quality pre-requisites for the FBW ARSENIC system: Iron < 0.3 ppm,

Manganese < 0.05 ppm, pH < 8.0, Silica < 30 ppm, Hardness > 5 gpg is preferred but not

required.

Once the system has been installed, an arsenic test should be done to determine if the

arsenic level is being reduced sufficiently (10 ppb or less, per the EPA MCL) and should be

tested regularly (every 6 months recommended) to ensure the system is functioning properly

and to indicate when the media has become exhausted.

Time of Backwash

Periodically the control valve will go through a backwash cycle. This cycle is factory preset to 12:00 A.M.

flushing the accumulated sediment and/or precipitant to the drain. After the backwashing process the unit is

now prepared for the next period of service.

Water Supply

This filter will function properly when the water supply is furnished by a jet pump, submersible pump, variable

speed (constant pressure) pump or community water supply. As with all other filter systems, however, it is

imperative that the well pump provides enough flow rate for the filter to adequately backwash. In order to

ensure sufficient backwash flow rate the following pumping rate test should be performed prior to installing the

FBW or FBW ARSENIC system.

1. Make certain no water is being drawn in the house.

2. Open spigot nearest pressure tank.

3. When well pump starts, close spigot and measure time (in seconds) to refill pressure tank (well pump

turns back off). This is Cycle Time.

4. Using a container of known volume, draw water from pressure tank and measure how many gallons

until the pump turns back on again. This is Draw Down.

5. Calculate pumping rate by dividing draw down by cycle time and multiplying by 60.

Draw Down (gallons)

X

60

=

Pumping Rate (gallons per minute)

Cycle Time (seconds)

Example: Draw down is 8 gallons

Cycle time is 65 seconds

8 gallons

X

60

=

7.4 gpm (gallons per minute)

65 seconds

Pre-installation Instructions (cont.)

4

Location Considerations

The proper location to install the FBW/FBW ARSENIC will ensure optimum filter performance and satisfactory

water quality. The following factors should be considered in selecting the location of this system.

1. The FBW/FBW ARSENIC must be installed after the pressure tank (private well system only).

2. The system should be installed as close as possible (preferably within 15’) to an adequate floor or

laundry drain capable of handling the backwash cycle volume and flow rate (refer to unit

specifications). An air gap should be provided between the FBW drain line and plumbing drain.

3. All water conditioning equipment should be installed at least 10’ prior to the water heater. Water

temperatures exceeding 100°F can damage the internal components of the control valve and filter

tank. An expansion tank may need to be installed in the line to the water heater in order to allow for

thermal expansion and comply with local plumbing codes.

4. Water pressure must not exceed the range of 25 - 100 psi.

5. The system must not be subject to freezing temperatures.

6. The control valve requires 115/120 V, 60 Hz electricity from a three prong outlet that is not wired to

a switch.

7. Never install a cartridge type filter prior to the FBW/FBW ARSENIC. Any cartridge or in-line filter (if

desired) may be installed after the FBW/FBW ARSENIC system. This will prevent restricting the

water flow and pressure available for backwash.

8. Appliances requiring extended periods of continuous or high flow water use (i.e. geothermal heat

pumps, swimming pools, lawn irrigation, outside hose bibs, etc.) should bypass the filter.

Typical Installation

Water Heater

Untreated Water

Untreated Water for

geothermal heat pumps,

swimming pools, lawn

irrigation, hose bibs etc.

FIGURE 1: Typical Installation

Filtered Hard Water

Iron Filter

(if required)

Softener

Brine Tank

Pressure Tank

Tank

Treated Water

Grounding Strap

Pre-installation Instructions (cont.)

FBW/FBW

ARSENIC

5

STEP 1: Unpack FBW/FBW ARSENIC filter unit, making sure to remove entire contents of the shipping

container prior to disposal.

STEP 2: With the FBW/FBW ARSENIC filter unit in the upright position, remove the control valve from

the mineral tank being careful to not pull the distributor out of the gravel at the bottom of

the tank.

STEP 3: Cover the top of the distributor tube with the included red cap and, using the included blue

media funnel, pour filter media(s) into the mineral tank. If using multiple filter media types, load

in the order of heaviest (most dense) to lightest (least dense). 12” – 14” of space MUST be left

empty at the top of the mineral tank to allow for media bed expansion during backwash and to

prevent filter media from being discharged through the drain line.

STEP 4: Use a garden hose or bucket to fill the media tank with water.

STEP 5: Clean mineral tank threads to remove any filter media. Remove red cap from distributor tube

and reinstall control valve by threading it securely onto the mineral tank. (O-ring seal; HAND

TIGHTEN ONLY!).

STEP 6: Use clips and screws provided and attach bypass valve to the inlet/outlet of the control valve.

See Figure 2 below.

STEP 7: Shut off all water at main supply. On private well system, turn off power to pump and drain

pressure tank. Make certain pressure is relieved from complete system by opening nearest

faucet to drain system. SHUT OFF FUEL / ELECTRICAL SUPPLY TO WATER HEATER.

STEP 8: Cut main supply line as required to fit plumbing to inlet and outlet of bypass valve. DO NOT

PLUMB INLET AND OUTLET BACKWARDS. Piping should be supported. Do not apply heat

to any fitting attached to the bypass or control valve. Perform all plumbing according to local

plumbing codes.

STEP 9: Attach plumbing. DO NOT apply heat to any fitting connected to bypass valve or control valve,

as damage may result to internal parts or connecting adapters. MAKE CERTAIN WATER

ENTERS THROUGH INLET AND DISCHARGES THROUGH OUTLET.

Installation Instructions

FIGURE 2: Top View of Control Valve

6

STEP 10: Use polyethylene drain line tubing provided (NO VINYL TUBING) to run drain line from control

valve discharge fitting to floor drain or sump pit capable of handling the backwash rate of the

filter (refer to specifications and flow rate on page 12). DISCHARGE END OF THE DRAIN

LINE MUST BE FIRMLY SECURED! There must be an air gap at the end of the drain line to

prevent siphoning of waste water and meet plumbing code. Total length of drain line should

be 15’ or less. AVOID OVERHEAD DRAINS.

STEP 11: Place bypass in the “Bypass” position (refer to Figure 3 below). Open main supply valve or turn

on power to pump on private well systems.

STEP 12: Plug the power cord into an un-switched electrical outlet.

STEP 13: Initiate a manual regeneration by turning the Manual Backwash Knob clockwise until the knob

engages the program wheel. You should hear one click. This is the “Backwash” position.

Then, unplug the control valve from the electrical outlet to prevent it from advancing

automatically.

STEP 14: Refer to Figure 3 (page 6) for appropriate bypass valve operation. Rotate bypass lever of

stainless steel bypass ¼ of the way to Service or until air and/or water begins to flow slowly to

drain.

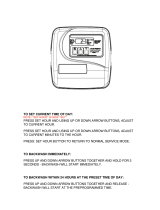

Backwash Timer Control

FIGURE 4a: Timer in Service Position

FIGURE 4b: Adjusting Time of Regeneration

Installation Instructions (cont.)

FIGURE 3: Stainless Steel Bypass Valve Operation

7

STEP 15: IMPORTANT: Activated Carbon, Filter Ag and Birm must be soaked for at least 2 hours

prior to submitting it to full flow rate to prevent loss of media to drain. Once the air is

purged, fully open the bypass valve to the “Service” position (Figure 3, Page 4) and leave the

control valve in “Backwash” position for at least 10 minutes or until water flowing from the drain

line runs clear; whichever is longer.

STEP 16: Plug the power cord back into an un-switched electrical outlet.

Manually advance the control valve to the “Service” position (Figure 4a) by turning the Manual

Backwash Knob clockwise and reconnect the control valve to the electrical outlet. Check for

and resolve any leaks in the unit or connected plumbing.

STEP 17: Set the Timer Control (Figure 4a) by rotating the Skipper Wheel (Figure 4a) so the red pointer

is directly over day 1. Select the days when backwashing will occur by sliding the metal tabs in

or out. IN indicates no backwashing will occur on that day, OUT indicates that backwashing

will occur on that day. Factory setting is to initiate backwash every third day.

IMPORTANT: Raw water quality determines the frequency of backwashing required. It is

recommended that the unit be backwashed NO LESS THAN every 6 days. If pressure drop

increases or contaminants are detected in the filtered water, backwashing frequency MUST be

increased. Filters with Calcite or Neutralizer media should be backwashed AT LEAST EVERY

OTHER DAY to prevent the media particles from “cementing” together.

STEP 18: Set the current time of day by depressing the red Time Set Button (Figure 4a) and turning the

24 Hour Gear (Figure 4a) to the desired time (note AM and PM).

STEP 19: Time of Regeneration is factory set to 12:00 A.M. To adjust the time of regeneration:

a) Unplug control valve from electrical outlet.

b) Locate three screws (Figure 4b) behind the Manual Backwash Knob (Figure 4a) by

pushing the red Time Set Button (Figure 4a) and rotating the 24 Hour Gear (Figure

4a) until each screw appears in the cut out portion of the Manual Backwash Knob.

c) Loosen each screw slightly to release the pressure on the time plate of the 24 Hour

Gear

d) Continue depressing the red Time Set Button and rotate the 24 Hour Gear to

expose the Regeneration Time Pointer (Figure 4a) in the cut out portion of the Manual

Backwash Knob. Keep the Regeneration Time Pointer visible in the cut out while

rotating only the time plate until the desired time of regeneration (note AM and PM) is

aligned with the Regeneration Time Pointer.

e) Continue depressing the red Time Set Button and rotate the 24 Hour Gear along

with the Time Plate until each screw has been exposed in the cut out portion of the

Manual Backwash Knob and re-tightened. DO NOT OVERTIGHTEN. Make certain

that the backwashing filter DOES NOT regenerate at the same time with any other

water treatment equipment.

STEP 20: Turn on fuel/electrical supply to water heater.

RECOMMENDED: Retain the red distributor cap and blue media funnel for future replenishment of filter media.

NOTE: If the FBW filter is loaded with any self-sacrificing media like Calcite or Neutralizer, mark the

media level on the side of the tank by shining a bright light through the tank to see its level. Replenish

the media in the mineral tank when the level drops by more than three inches.

Installation Instructions (cont.)

8

How to set Time of Day:

1. Press and hold the red button to disengage the drive gear.

2. Turn the large 24 hour gear until the actual time of day is at the time of day pointer.

3. Release the red button to again engage the drive gear.

How to set the Days of Backwash:

1. Rotate the skipper wheel until the number 1 is at the red pointer.

2. Each number represents a day. The number by the red pointer is tonight.

3. Slide the metal tabs outward on the desired days of regeneration.

How to Manually Initiate a Backwash Cycle:

1. Grab the manual regeneration knob and turn clockwise.

2. The drive gear will engage the program wheel and make a complete revolution through the

backwash cycle.

3. The backwash knob will make a complete revolution and return to the home position after the

backwash cycle.

Timer Operation

FIGURE 5: Front of Timer Assembly

9

How to Change the Length of Backwash Cycles:

All cycles have been factory set and should not need adjustment. If local conditions require different

cycle lengths, however, the following procedures should be followed.

1. Grasp top left corner of timer assembly and pull to swing timer open and expose the program

wheel.

2. Remove program wheel from timer by squeezing retaining lugs in center of program wheel.

Maneuver program wheel away from micro switch arms and timer assembly.

3. BACKWASH cycle may be lengthened by adding pins to 1st set of pins on program wheel. Each

pin will equal 2 minutes of backwash time. The remaining two sets of pins MUST also be

shifted clockwise to ensure 2 holes separate each cycle.

4. RAPID RINSE cycle may be lengthened by adding pins to the 2nd set of pins on the program

wheel. Each pin represents 2 minutes of rapid rinse time. The last set of pins MUST also be

shifted clockwise to ensure 2 holes separate each cycle.

5. Reinstall the program wheel on the retaining lugs by maneuvering past the micro switch arms.

6. Close and latch the timer assembly. Ensure that the retainer snaps into the hole in the back plate

and all electrical wiring is ABOVE the timer post.

FIGURE 6: Back of Timer Assembly

Timer Operation (cont.)

10

1) At least every six months you should check the time of day setting. Power outages will cause the units

time clock to be inaccurate and backwashing will not occur at the planned time.

2) If your unit contains activated carbon, you must replace the carbon and gravel underbed at least every

three years. Replacement may be required sooner if the taste and odor being removed begins to

reappear in the treated water or you experience increasing pressure drop that is not resolved by

increasing the frequency of backwashing.

3) Filter Ag and Filter Sand will last indefinitely. It may be necessary to replace them if you experience

increasing pressure drop that is not resolved by increasing the frequency of backwashing or if water

quality diminishes due to contaminant bleed through.

4) Neutralizer media or calcite must be replenished at least annually. Mark the side of the mineral tank at

installation so the drop in media level may be monitored by shining a bright light behind the mineral

tank. Add media if the level has dropped by more than three inches.

5) Birm should be replaced when iron reappears in the treated water and backwashing does not improve

the water quality.

6) For the FBW ARSENIC test the treated water for arsenic every 6 months to ensure the system is

functioning properly and to identify when the arsenic reduction media has become exhausted.

Satisfactory test results will be 10 ppb of arsenic or less. If unsatisfactory the filter will need to be re-

bedded.

TO REPLENISH OR REBED MEDIA:

1) Pressure must be relieved on the system by placing the bypass valve in the “Bypass” position (Figure

3) and rotating the manual backwash knob (Figure 4a) clockwise until the knob engages the program

wheel and water flows briefly to drain. Once water has stopped flowing to drain move on to next step.

2) Unplug the control valve from the electrical outlet to prevent it from advancing automatically.

3) Disconnect the control Valve from the bypass valve

4) Disconnect the drain line from the control valve

5) Unscrew control valve from mineral tank (IF REBEDDING ONLY - remove the distributor).

6) Siphon water from mineral tank (IF REBEDDING ONLY - Remove existing media and gravel).

7) IF REBEDDING ONLY - Rinse mineral tank and replace distributor, making certain that the

distributor basket sits in the center of the tank bottom.

8) Cover the top of the distributor tube to prevent media entering the tube during filling. Using a funnel,

pour filter media(s) into the mineral tank. (IF REBEDDING ONLY - Begin loading tank with the

gravel underbed. Filling the mineral tank 1/3 with water before loading gravel will cushion the

fall and ensure even distribution of the gravel and media. If using multiple filter media types,

load in the order of heaviest {most dense} to lightest {least dense}.) 12” – 14” of space MUST be

left empty at the top of the mineral tank to allow for media bed expansion during backwash and to

prevent filter media from being discharged through the drain line.

Maintenance

11

9) Use a garden hose or bucket to fill the media tank with water.

10) Clean mineral tank threads to remove any filter media. Uncover distributor tube and reinstall control

valve by threading it securely onto the mineral tank. (O-ring seal: HAND TIGHTEN ONLY!)

11) Attach bypass (Figures 2 & 3) to control valve body.

12) Re-attach drain line to control valve.

13) IMPORTANT: Activated Carbon, Filter Ag and Birm must be soaked for at least 2 hours prior to

submitting it to full flow rate to prevent loss of media to drain.

14) Open the bypass valve only 1/4 of the way to the “Service” position (Figure 3, Page 4). Any air trapped

in the media bed should begin purging to the drain and water should begin flowing slowly to the drain.

15) Once the air is purged, fully open the bypass valve to the “Service” position (Figure 3, Page 4) and

leave the control valve in “Backwash” position for at least 10 minutes or until water flowing from the

drain line runs clear; whichever is longer.

16) Plug the power cord back into an un-switched electrical outlet.

17) Manually advance the control valve to the “Service” position (Figure 4a) by turning the Manual

Backwash Knob clockwise. Check for and resolve any leaks in the unit or connected plumbing.

Maintenance (cont.)

12

Description

FBW10

FBW15

FBW20

FBW25

FBW30

FBW40

Filter Media Volume, cu. ft.

1.0

1.5

2.0

2.5

3.0

4.0

Gravel Underbed, lbs.

20

20

25

25

50

50

Operating Flow Rate, gpm

Continuous

(no duration limit, 5 gpm/ft

2

)

2

3

4

5

5

7

Service

(intermittent flow up to 10 gpm/ft

2

)

5

6

8

9

11

14

Peak

(10 mins. or less, 15 gpm/ft

2

)

8

9

12

14

16

21

Backwash Flow Rate, gpm

5

5

7

7

10

10

Service Pipe Size, in.

Standard

¾

¾

¾

¾

¾

¾

-1 Suffix on Model Number

1

1

1

1

1

1

Tank Diameter x Height, in.

10 x 44

10 x 54

12 x 48

13 x 54

14 x 65

16 x 65

Minimum Space Required, in.

Width

12

12

13

14

15

17

Depth

15

15

15

15

15

17

Height

54

64

58

64

75

75

Approximate Ship Wt., lbs.

49

52

60

75

99

115

(Media Not Included)

Description

FBW10ARSENIC

FBW20ARSENIC

FBW30ARSENIC

FBW40ARSENIC

Filter Media Volume, cu. ft.

1.0

2.0

3.0

4.0

Gravel Underbed, lbs.

20

25

50

50

Operating Flow Rate, gpm

Service (10 gpm/ft

2

media surface)

*<=30ppb **<=40ppb ***<=50ppb

6*

8**

11***

14***

Peak (<=15 psi loss)

Exceeding peak flow can damage the media!

11

12

13

14

Backwash Flow Rate, gpm

5

7

9

10

Pressure Loss, psi

@ Service

5

8

11

15

@ Peak

12

14

14

15

Service Pipe Size, in.

Standard

¾

¾

1

1

-1 Suffix on Model Number

1

1

-NA-

-NA-

Tank Diameter x Height, in.

10 x 44

12 x 48

14 x 65

16 x 65

Minimum Space Required, in.

Width

12

13

15

16

Depth

15

16

17

18

Height

54

58

75

75

Approximate Ship Wt., lbs.

112

168

287

343

Specifications

13

3

1

4

5

6

2

Component Parts Breakdown

14

*Filter media sold seperately. Select appropriate media for water condition (page 2).

Ref #

Part Number

Description

1

FBW10 Vlv Assy L/BP

Control Valve, Cover, 5.0 GPM DLFC, less bypass

for models FBW10, FBW15, & FBW10ARSENIC

FBW20 Vlv Assy L/BP

Control Valve, Cover, 7.0 GPM DLFC, less bypass

for model FBW20, FBW25, & FBW20ARSENIC

FBW30 Vlv Assy L/BP

Control Valve, Cover, Blank DLFC, less bypass for

model FBW30, FBW40, FBW30ARSENIC, &

FBW40ARSENIC

2

18280-02

Top Screen, Bayonet Style

3

D100S-48

Distributor Tube, 1" x 48"

for models FBW10, FBW20, FBW10ARSENIC, &

FBW20ARSENIC

D100S-54

Distributor Tube, 1" x 54"

for model FBW15 & FBW25

D100S-65

Distributor Tube, 1" x 65"

for model FBW30, FBW40, FBW30ARSENIC, &

FBW40ARSENIC

4

MTP1044N

10 x 44 Mineral Tank, Nat, Base, 2.5" Top Opening

For model FBW10 & FBW10ARSENIC

MTP1054N

10 x 54 Mineral Tank, Nat, Base, 2.5" Top Opening

For model FBW15

MTP1248N

12 x 48 Mineral Tank, Nat, Base, 2.5" Top Opening

For model FBW20 & FBW20ARSENIC

MTP1354N

13 x 54 Mineral Tank, Nat, Base, 2.5" Top Opening

For model FBW25

MTP1465N

14 x 65 Mineral Tank, Nat, Base, 2.5" Top Opening

For model FBW30 & FBW30ARSENIC

MTP1665N-4.0

16 x 65 Mineral Tank, Nat, Base, 4.0" Top Opening

For model FBW40 & FBW40ARSENIC

(SF4821-2 4x2.5 bushing also required)

5*

A10

Activated Carbon, 1.00 cu. ft. bag

A05P

Activated Carbon, 0.50 cu. ft. pail

ACC10

Catalytic Carbon, 1.00 cu. ft. bag

ACC05P

Catalytic Carbon, 0.50 cu. ft. pail

ARSENIC-10

Arsenic Media, 1.00 cu. ft. bag (FBW-ARSENIC)

B10

Birm, 1.00 cu. ft. bag

B05P

Birm, 0.50 cu. ft. pail

C05P

Calcite, 0.50 cu. ft. pail

FA10

Filter Ag, 1.00 cu. ft. bag

FA05P

Filter Ag, 0.50 cu. ft. pail

ZEO10

Zeolite 1.00 cu. ft. bag

Z05P

Zeolite 0.50 cu. ft. pail

N05

Neutralizer, 0.50 cu. ft. pail

QFS05P

Quartz Filter Sand, 0.50 cu. ft. pail

6

QC20

1/4" x 1/8" Gravel, 20 lb Pail

for models FBW10, FBW15, & FBW10ARSENIC

QC25

1/4" x 1/8" Gravel, 25 lb Pail

For models FBW20, FBW25, & FBW20ARSENIC

QC50

1/4" x 1/8" Gravel, 50 lb Bag

For models FBW30 , FBW40, FBW30ARSENIC, &

FBW40ARSENIC

Component Parts List

15

Control Valve Breakdown

16

REF #

Part Number

Description

REF #

Part

Number

Description

A

60040SS

Stainless Steel Bypass, 3/4”

FPT (Standard)

7

18312

Retainer, Drain

60041SS

Stainless Steel Bypass, 1”

FPT (Optional, “-1S” suffix)

8

12092

5.0 gpm DLFC

(FBW10 &FBW15)

B

60900-41

Coupling Kit

12408

7.0 gpm DLFC

(FBW20 & FBW25)

Not

Shown

60705-50

5.0 gpm DLFC Housing

(Old Style for 1 & 1.5 cu ft)

-NA-

No DLFC used

(FBW30 & FBW40)

60705-70

7.0 gpm DLFC Housing

(Old Style for 2 & 2.5 cu ft)

Not

Shown

12338

Drain Fitting, Hose Barb, 90

Deg Elbow, 1/2" x 1/2" (Old

Style)

60705-00

Blank DLFC Housing

(Old Style for 3 & 4 cu ft)

10

19936

Base Seal (2510)

C

60705-50A

5.0 gpm DLFC Elbow

(New Style for 1 & 1.5 cu ft)

11

19322

2510 Adapter Base

60705-70A

7.0 gpm DLFC Elbow

(New Style for 2 & 2.5 cu ft)

12

19197

Slip Ring

60705-00A

Blank DLFC Elbow

(New Style for 3 & 4 cu ft)

13

18303

Tank O-Ring, 2510 Valve

D

60090

Piston Assembly

14

13304

Distributor O-Ring, -121

E

60121

Seal and Spacer Kit

15

13030

Distributor Retainer

F

FV2510-1PH

Power Head Assembly,

2510 TC with Cover

16

13911

Main Drive Gear

G

60050-21

Drive Motor Assembly

17

18743-1

Timer Motor, 120v/60Hz,

2510/5600 Valve

H

60160-10

Drive Cam Assembly, STF

18

15320

Micro Switch, Homing

I

60304-13

Timer Assembly, 3200, 12

Day, STF, 120/60

19

10896

Micro Switch, Step

1

14105

Bypass Valve Seal, Single

Lever

20

10218

Micro Switch, Drive Motor

2

13305

Coupling O-Ring, -019

21

10909

Connecting Link Pin

3

19228-01

Coupling, Adapter S/ASSY

22

10338

Roll Pin

4

10692

Injector cover screw

23

12777

Brine Cam, STF

5

11893

Injector Cover

24

60219-02

Valve Cover, Environmental

(Old Style)

6

14805

Injector Body Gasket

SCA-926

Valve Cover, Environmental

(New Style)

Control Valve Parts List

17

PROBLEM

CAUSES

SOLUTIONS

Excessive pressure

drop through filter

A) Filter not

backwashing

B) Filter bed loaded

with sand

C) “Cementing” or

“Channeling”

D) Drain line restricted

E) Top Screen Fouled

F) Control Valve

plugged with debris

1) Check timer motor and replace if faulty

2) Ensure uninterrupted power supply

3) Check Backwash frequency setup

4) Verify sediment being removed is less

dense than the filter media and install a

“Spin-Down” type sediment filter ahead

of the FBW to remove well sand

5) Verify adequate pumping rate for

backwash

6) Probe media bed to check for

“Cementing”

7) Check drain line for restriction: frozen,

plugged, kinked, exceeds 15’, overhead

installation, flexible drain line, drain line

diameter too small

8) Remove and clean top screen

9) Disassemble and clean control valve

Contaminant not being

properly removed

A) Leaking bypass

valve

B) Internal valve leak

C) Distributor not

seated properly in

control valve

D) Water usage flow

rate exceeds filter

specifications

1) Verify bypass valve is in service position

2) Replace piston, spacers and seals

3) Verify distributor tube seated securely in

control valve body

4) Verify actual water usage flow rates

against system specifications

5) Increase length of backwash and rinse

cycles

Neutralizer media

raises pH too high

A) Filter is brand new

B) Wrong media used

1) Turn bypass valve very slightly to the

“Bypass” position allowing a small

amount of untreated water to bleed into

the treated water

2) Rebed the unit with a less aggressive

media

Neutralizer media fails

to raise pH sufficiently

A) Water usage flow

rate is too high to

provide adequate

contact time

B) Media bed is

“Cemented” or

“Channeled”

1) Verify actual water usage flow rates

against system specifications

2) Verify adequate pumping rate for

backwash

3) Check drain line for restriction: frozen,

plugged, kinked, exceeds 15’, overhead

installation, flexible drain line, drain line

diameter too small

Birm Filter fails to

remove iron

A) pH too low

B) Dissolved oxygen

level too low

1) pH of untreated water must be 6.8 or

higher – adjust with proper equipment

2) Aerator may be installed prior to the filter

Loss of media

to drain

A) Air in system

B) Insufficient soak

time before first

backwash after

installing media

1) Ensure well system has proper air

elimination control

2) Check media level and adjust if

necessary

Howling or whistling

noise during

regeneration

A) Inadequate drain

line diameter or

drain line restricted

1) Reconfigure or replace drain line

Troubleshooting

18

PROBLEM

CAUSES

SOLUTIONS

Control Valve

cycles continually

A) Faulty switch

B) Faulty timer motor

1) Replace faulty switch

2) Replace faulty timer motor

Continuous flow of

water to drain

A) Loss of electrical

power during

regeneration

B) Program wheel

setup incorrectly

C) Debris in control

valve

D) Internal leak in

control valve

E) Drive motor faulty

1) Ensure electrical outlet is functioning

2) Verify timer programming

3) Disassemble and clean control valve

4) Replace seals and/or piston

5) Replace faulty drive motor

Media in the

service lines

A) Unit installed

backwards

1) Re-plumb the water lines so that the

supply side of the line is connected to the

inlet of the bypass and the service side is

connected to the outlet.

Troubleshooting

19

Control Valve Wiring Diagram

/