GE OSMONICS

F-801 INTERNAL REVERSE OSMOSIS UNIT

Operation

and Maintenance Manual

Revision E

This Revision Supersedes P/n 12552 Rev. D

12552e

A

A 27 February 2004

F-801 INTERNAL REVERSE OSMOSIS UNIT

Installation, Operation and Maintenance Manual

TABLE OF CONTENTS

Page

CHAPTER ONE: GENERAL INFORMATION 1-1

Section 1.1 The Manual 1-3

1.2 Safety Summary 1-3

1.3 Applications 1-4

1.4 Contraindications 1-4

1.5 Environmental Considerations 1-5

1.6 Theory of Operation 1-6

1.7 Fluid Components 1-7

1.8 Monitors and Controls 1-9

1.9 Optional Equipment 1-11

1.10

1.10.1

1.10.2

1.10.3

1.10.4

1.10.5

Specifications

Inlet Water Requirements

Flow Rates

Electrical Requirements

Membrane Performance Characteristics

Environmental Requirements

1-12

1.11 Disposal 1-13

1.12 Electromagnetic Interference 1-13

1.13 Service Assistance 1-14

1.14 Return Goods Authorization (RGA) 1-15

1.15 Symbols and Abbreviations 1-16

CHAPTER TWO: INSTALLATION GUIDELINES AND INITIAL

SYSTEM START UP

2-1

Section 2.1 Installation Considerations 2-3

2.2 Installation Procedure 2-3

2.3 Product Water Analysis Procedure 2-5

CHAPTER THREE: SYSTEM OPERATION 3-1

Section 3.1 Daily Start-up Procedure 3-3

3.2 Bicarbonate Container Filling 3-6

3.3 Shut Down Procedure 3-6

12552e

B

B 27 February 2004

CHAPTER FOUR: ROUTINE MAINTENANCE 4-1

Section 4.1

4.1.1

Routine Maintenance of F-801 Internal RO

System

Daily / Per Treatment Maintenance

4-3

4-3

4.1.2 Weekly Maintenance 4-5

4.1.3 Monthly Maintenance 4-5

4.1.4 Quarterly Maintenance 4-6

4.1.5 Annual Maintenance 4-6

4.2

4.2.1

Specific Maintenance Procedures and Instructions

Motor Lubricant Procedure

4-7

4-7

4.2.2 Leak Repair 4-7

4.2.3 Pre-filter Replacement 4-9

4.3 F-801 Cleaning Indications 4-11

4.3.1 Pre-Cleaning Preparation 4-12

4.3.1.1 Pre-Cleaning Procedure 4-12

4.3.1.2 Cleaner Recirculation and Dwell Time 4-13

4.3.1.3 Post-Cleaning Rinse Procedure 4-14

4.3.2 BIOSAN Pre Cleaning Preparation 4-16

4.3.2.1 BIOSAN Cleaning Procedure 4-16

4.3.2.2 BIOSAN Recirculation and Dwell Time 4-17

4.3.2.3 BIOSAN Post Cleaning Rinse Procedure 4-18

4.4 F-801 Disinfection Indications 4-20

4.4.1 Formaldehyde Disinfection Preparation 4-20

4.4.1.1 Formaldehyde Pre-Disinfection Procedure 4-21

4.4.1.2 Formaldehyde Disinfection and Dwell Time 4-22

4.4.1.3 Formaldehyde Post-Disinfection Rinse Procedure 4-23

4.4.2 “RENALIN®” Disinfection Procedure

(Peracetic Acid and Peroxide-Based Compounds

such as Renalin®, Minncare™, & Peracidin™)

4-24

4.4.2.1 “RENALIN®” Pre-Disinfection Preparation 4-25

4.4.2.2 “RENALIN®” Disinfection and Dwell Time 4-26

4.4.2.3 “RENALIN®” Post-Disinfection Rinse Procedure 4-28

4.5 Product Water Culture 4-29

4.5.1 Product Water Culture Procedure 4-30

4.6 System Storage 4-31

4.6.1 Formaldehyde Storage Procedure 4-31

4.6.2 BIOSAN Storage Procedure 4-32

12552e

C

C 27 February 2004

CHAPTER FIVE: TROUBLESHOOTING 5-1

Table of Content 5-3

Section 5.1 RO Fails to Run 5-5

5.2 RO Runs Intermittently 5-5

5.3 Motor Runs Hot 5-6

5.4 Low Pump Pressure 5-6

5.5 Pressure Gauge Vibrates Erratically 5-7

5.6 Excess Product Pressure (too high) 5-7

5.7 Product Flow Too Low 5-7

5.8 Product Flow Too High 5-8

5.9 Membrane Product Pressure Too Low 5-9

5.10 Leaks 5-9

5.11 Low Percent Rejection 5-9

5.12 Rejection Display Fluctuates 5-10

5.13 TDS Value High 5-10

5.14 RO Fails to Draw Disinfectant 5-11

5.15 RO Pump Leaks 5-12

CHAPTER SIX: DRAWINGS 6-1

CHAPTER SEVEN: SPARE PARTS LIST 7-1

12552e

D

D 27 February 2004

This page intentionally left blank

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 1 General Information

F-801 Internal RO System

CHAPTER ONE:

GENERAL INFORMATION

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 2 General Information

This page intentionally left blank.

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 3 General Information

1.1 The Manual

This manual has been prepared to provide the operator with information and

instructions regarding the installation, use, maintenance and troubleshooting of the GE

Osmonics F-801 Internal Reverse Osmosis System.

CAUTION:

When used as a medical device, Federal law restricts this device to sale by or on

the order of a physician. Per CFR 801.109 (b)(1).

The manual has been written in narrative form supplemented with schematics and

drawings for clarification. The operator can perform most procedures mentioned in

this manual. Any exceptions will be clearly identified by a qualifying statement.

1.2 Safety Summary

Words in BOLD CAPITAL letters are used to identify labels on the device and key

safety or qualifying statements. A list of all symbols and abbreviations is located at the

end of this chapter. See Technote 120 for a glossary of relevant terms.

This safety summary does not contain all of the safety statements in the manual. Other

safety statements are included within the manual text and are enhanced and defined as

follows:

NOTE:

Statements that provide further clarification.

CAUTION:

Statements identifying conditions or practices that could result in equipment or

other property damage.

WARNING:

Statements identifying conditions or practices that could result in personal injury

or loss of life.

READ THIS MANUAL:

Prior to operating or servicing this device, this manual must be read and understood.

Keep this and other associated manuals for future reference and for new operators or

qualified service personnel. A note sheet is provided at the end of each chapter for

operators to make notations that may be valuable to other users.

USE PROPER POWER CONNECTIONS:

Use proper wiring and connection methods to satisfy hospital electrical codes.

DO NOT REMOVE COVERS OR PANELS:

To avoid electrical shock hazard, do not remove covers or panels when power is

supplied to the device. Do not operate the device when covers or panels are removed.

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 4 General Information

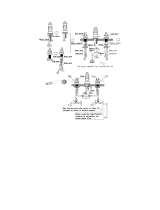

USE PROPER WATER AND DRAIN CONNECTIONS:

Use proper water and drain connections to prevent contamination of the RO and danger

to the patient. To ease confusion, the Quick Disconnect (QD) fittings have been color-

coded. Both the male and female fittings are colored. The color coding is; Green =

FEED water, Red = WASTE water, White = PERMEATE (Product) water.

SHOCK HAZARD:

Connect this device to a proper ground connection in accordance with the National

Electrical Code. DO NOT under any circumstances remove the ground wire or ground

prong from any power plug. DO NOT use an extension cord with this equipment.

Keep the surface under the RO(s) free of liquids. Fix any leaks from the hemodialysis

unit promptly.

DEVICE LABELING:

Do not under any circumstances; remove any Caution, Warning or any other

descriptive labels from the devices until the conditions warranting the label are

eliminated.

DO NOT OPERATE IN A FLAMMABLE ATMOSPHERE:

To avoid fire or explosion, do not operate this device in an explosive environment or

near flammable anesthetics.

DO NOT TRY TO CATCH THE EQUIPMENT IF IT STARTS TO FALL OVER:

The overall assembly is weighty and can cause physical harm.

1.3 Applications

The F-801 Internal Reverse Osmosis (RO) System is designed to purify water by

forcing water through a semi-permeable RO membrane. Water purified by reverse

osmosis has had approximately 95% of the dissolved ions and approximately 99% of

most other contaminants removed. The quality of the purified water, referred to as

product water or permeate, depends on the quality of the feed water and normally is

equal to or exceeds AAMI standards. Such water is suitable for hemodialysis

applications.

1.4 Contraindications

WARNING:

GE Osmonics systems are not designed, sold, or intended for use in producing

water for injection

Furthermore, GE Osmonics systems are not intended to be used outside of the device

specifications and limitations, as outlined in this manual and other related materials.

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 5 General Information

1.5 Environmental Considerations

Prior to the installation of the F-801 RO System, it will be necessary to provide utilities

and create an environment suitable for the trouble free operation of the RO system and

its accessories.

POWER:

The F-801 operates on 115 VAC single-phase power. Histories of power failure,

power surges, and low line voltages should be noted and reported to the

manufacturer or their agent as they may create adverse conditions for the

operation of equipment.

WATER:

Reverse osmosis systems require a reliable water source. The F-801 RO needs a

minimum of 30-PSI pressure at a minimum flow of 1.6 gallons per minute. It is

important that water is flowing at the design flow rate when testing water pressure

rather than reading static pressure.

DRAIN:

A drain outlet is required by the RO system. The drain must have a minimum

capacity of 1.6 gallons per RO per minute of continuous flow for as long as and

as often as the RO is operating.

TEMPERATURE:

The F-801 RO is normally connected to a cold water supply. The performance

specifications of the RO are based on 77°F (25°C) feed temperature. Each degree

Fahrenheit the feed water temperature falls, the RO product flow decreases

approximately 1.5%, and each degree Celsius drop, the product flow is reduced

by 3% (See Technote 113 for the “Temperature Correction Factors” chart). In

climates where the winter water temperature drops significantly below 77°F it

may be necessary to temper (heat) the water.

WARNING:

The temperature of the tempered water should be monitored closely with a

thermometer as high temperatures can damage the RO membranes and possibly

harm the patient. Refer to the inlet water requirements (Section 1.10.1) for the

maximum operating temperature for the F-801 RO.

CAUTION:

It is necessary to keep the RO from freezing to prevent serious damage to the RO

unit.

NOISE:

The RO unit does not generate significant noise levels. Hard walls may reflect

noise and will make the RO seem louder.

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 6 General Information

WATER PURITY:

Plumbing materials can significantly contribute to the contamination of the water.

Metallic pipes (with the exception of 316 stainless steel) must be eliminated once

the purification process has begun. Schedule 40 or 80 PVC pipes, polypropylene,

PVDF, and other FDA recommended materials are suitable for most grades of

purified water. Care must also be exercised in the choice of a thread sealant.

Teflon tape is suitable for all threaded connections in this system.

WARNING:

Ordinary pipe dope must be avoided since it may leach objectionable and

potentially dangerous impurities into the water.

1.6 Theory of Operation

The F-801 Portable Reverse Osmosis system (RO) purifies a given feed water (by way

of reverse osmosis) for use in hemodialysis applications. The F-801 RO possesses

monitoring for pressure, product water quality and membrane performance (percent

rejection). The unit includes pre-filtration to remove particulates greater than 5

microns, which could clog orifices or damage components. The RO pump provides the

pressure required to push water through the RO membrane. The fluid controls provide

a means of managing flow rates and pressures. The following paragraphs detail the

function of these fluid control components, which are used within the RO.

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 7 General Information

1.7 Fluid Components

Pre-filter:

From the feed water, the fluid path flows through the softener (optional) on

through the carbon tank and then into the pre-filter, located in a blue housing

mounted on the side of the hemodialysis unit. It is a cartridge type filter with a

nominal filtration rating of five microns.

Pressure Adjust Regulator:

Used to adjust the product pressure. The pressure is displayed on the product

pressure gauge, on the front of the RO.

High-Pressure Pump:

Provides up to a 200 PSI boost of the inlet water to the Reverse Osmosis

Membrane Assembly (ROMA). The RO pump pressure is displayed on a 0 to

300 PSI gauge mounted outside the RO, below the product pressure gauge. The

pressure is factory set at 150 PSI.

Reverse Osmosis Membrane Assembly (ROMA):

One is included in the F-801 RO. A ROMA is an assembly that includes the

membrane housing, end caps, fittings, and a membrane. The thin film membrane

will produce 600 (±15%) gallons per day of product water, depending on

membrane condition and water temperature.

Waste Flow:

The Waste Flow is controlled by a length of 1/8" capillary tubing. The length of

the tube is factory determined to correctly govern the wastewater flow to drain.

CAUTION:

This tube must not be shortened.

Dialyze/Flush Valve:

The Dialyze/Flush Valve is used to flush the membrane surface of rejected

contaminants, and to accelerate the rinse out of cleaners or disinfectants from the

RO. Some pump noise (chattering) is normal in the flush position. The RO is in

"flush" from the full open (flush) to just before the fully closed (dialyze) position.

CAUTION:

Excessive “chattering” may be eliminated by slowly moving the valve from the

full flush position towards “DIALYZE”.

Product Recirculation Check Valve:

Prevents over-pressuring of the product supply. When the product pressure

exceeds the set point of the pressure regulator, the product recirculation check

valve opens. Excess product water is then recirculated back to the inlet water

flow.

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 8 General Information

Feed Port:

The Feed Port is a green colored quick-disconnection port for the introduction of

feed water to the RO. The port has a check valve that closes when there is no

hose connected to the fitting.

Product Port:

The Product Port is a white colored quick-disconnection port for the output of

purified product water. The port has a check valve that closes when there is no

hose connected to the fitting.

Waste Port:

The Waste Port is a red colored quick-disconnection port for the output of

concentrate or waste to the drain. The port has a check valve that closes when

there is no hose connected to the fitting.

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 9 General Information

1.8 Monitors and Controls

RO Power Switch:

The RO Power Switch is mounted on the back of the remote monitor module.

The switch is used to turn the F-801 RO unit on and off.

Inlet Water Sensor:

Monitors the quality of the inlet water. Inlet quality is compared to the outlet

(product) water quality and is displayed as "percent rejection" on the front panel.

Product Water Sensor:

The Product Water Sensor is used in conjunction with the inlet water sensor by

the percent-rejection circuitry to calculate the membrane rejection rate. The rate

of rejection is displayed from 70% - 99% in a 5 LED array on the front panel.

Total Dissolved Solids (TDS) Sensor:

Samples the product water quality via the sensor probe, and the final quality of the

product water is indicated on a digital display on the front panel as TDS in mg/L

and ppm. The monitor is temperature compensated to adjust the display value to

changing water temperature.

Pressure Adjust Regulator:

The Pressure Adjust Regulator inside the RO is used to set the maximum product

pressure needed to supply a dialysis machine. Adjusting this regulator will also

result in small adjustments in the pump pressure.

Pre and Post filter Pressure Gauges:

The Pre-filter pressure gauges are mounted on top of the pre-filter housing and

display the feed water pressure from zero to 100 PSI. The two gauges are used to

determine the feed water pressure and when compared against each other to

determine fouling of the filter (delta pressure).

Product Pressure Gauge:

The Product Pressure Gauge reads the product pressure from 0 to 100 PSI and is

located on the RO module right side panel. Product pressure will read zero (or

close to) when the product line is not connected to a dialysis unit and the product

hose is connected to the product fitting and the valve is open. The Fresenius

dialysis machine requires a minimum inlet pressure of 20 PSI.

Pump Pressure Gauge:

The Pump Pressure Gauge reads the pump pressure from 0 to 300 PSI and is

located on the RO module right side panel. It is used for monitoring during

operation and when adjusting the pump pressure, and is located on the front of the

RO.

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 10 General Information

Dialyze/Flush Valve:

The Dialyze/Flush Valve is a 1/4-turn ball valve. When in the dialyze mode, the

valve is in the closed position. When the valve is turned at any point towards

flush, the valve is open. The closer to the flush point, the more the valve is open.

When in flush, the valve bypasses the waste flow tube.

Percent Rejection Display:

The Percent Rejection Display is a 5 LED array that indicates how the RO

membranes are performing. The lights correspond to 99%, 95%, 90%, 85%, and

>70% rejection. The 99% light, when illuminated, indicates a need to evaluate

the RO system performance. RO units do not normally perform in excess of

99%; verify this reading with an independent meter and take corrective action if

indicated. Some RO membranes will achieve this level of performance under

optimum conditions.

Product Water Total Dissolved Solids (TDS) Display:

The Product Water Total Dissolved Solids (TDS) digital display indicates product

water purity in mg/L (ppm). It is temperature compensated to adjust the value of

the display with changing water temperature for better accuracy.

Less Than 0.5 mg/L Check System Lamp:

The Less Than 0.5 mg/L Check System lamp illuminates when the TDS reading is

0.5 mg/L or less. This indicates a need to evaluate the RO system performance.

RO units do not normally have this low product TDS. Verify this reading with an

independent meter and take corrective action if indicated.

NOTE:

RO membranes may achieve this level of performance under optimum conditions

(good feed water).

Alarm Set:

The Alarm Set switch allows the operator to set the TDS levels at which the alarm

will sound. The alarm should be set at twice the initial TDS reading. If the set

point is exceeded, an audible alarm will sound.

NOTE:

Choose the alarm set point that is closest to twice the initial installation TDS

reading.

Alarm Mute:

The Alarm Mute switch will mute the audible alarm for 30 - 45 seconds. A red

indicator lamp is displayed on the switch when the mute switch has been pressed.

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 11 General Information

1.9 Optional Equipment

GE Osmonics offers a number of optional items to adapt the equipment to meet specific

needs. Options are available to improve the quality of the feedwater to the RO.

Frequently requested options are briefly described in the following paragraphs. If more

information is needed, or if other options are desired, please consult the factory. Refer

to Chapter xx for catalog part numbers.

Carbon Filter Tanks remove chlorine/chloramine from the feed water, preventing

damage to the RO membrane and injury to patients. The filter incorporates a bed of

granular activated carbon. Two sizes of carbon tanks come in semi-automatic control

valve and exchange head styles.

WARNING:

Carbon is not regenerated and must be replaced when exhausted.

WARNING:

A suitable carbon filter should always be present as pretreatment for the RO unit

in order to prevent chlorine/chloramine damage to the thin film RO membrane

and harm to the patient. GE Osmonics strongly recommends the use of two

carbon tanks, used in a series configuration.

Softeners remove calcium, magnesium, and other scale producing contaminants from

the feed water. Their removal prevents the build-up of scale on the membrane surface.

A control valve drives the regeneration of the softener, and will remove the hardness

ions with a brine solution and rinse the ion exchange bed afterwards. The control valve

is normally governed by a semi-automatic time clock. There are two sizes of softener

tanks available.

Multi-Media Filter Tanks are a multi layered filtration system that consists of various

sized rocks as the media layers. The media are selected on the basis of their size and

specific gravities. Capable of removing ninety-eight percent of all particles greater than

ten microns, the multi-media filter is employed to remove suspended solids and

particulates from the water. The use of the multi-media filter will extend the life of the

pre-filter and RO membrane. Multi-media filters are not portable and not commonly

used with portable RO systems.

Dealkalizers are used to lower the pH of alkaline feed water. Water with pH levels

above 8.5 with chloramines present can reduce the performance of the carbon filters

and thin-film membranes. A control valve drives the regeneration rinsing of the

dealkalizer. The control valve is normally governed by a semi-automatic time clock.

There are two sizes of dealkalizer tanks available.

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 12 General Information

1.10 Specifications:

1.10.1 Input Water Requirements

Minimum

Maximum

Input flow Rate 2.0 GPM N/A

Temperature (water) 10°C (50°F) 32°C (90°F)

NOTE:

Operating at lower temperatures may make it impossible for the F-801 RO to

produce adequate permeate for the dialysis machine.

pH (operating) 5.5 10.5

TF Membranes

pH w/chloramines present (operating) 5.5 8.5

TF Membranes

pH (cleaning) 2.0 11.0

TF Membranes

Pressure, dynamic 30 PSI 100 PSI

1.10.2 Flow Rates

Product Flow based on the following conditions:

New Membranes

Operating Pressure: 150 PSI

Product Pressure: 1 PSI

Feed Water Temperature: 77°F (25°C)

GPM

LPM GPD LPD

.41 1.55 588 2225.8

Membrane flux may vary ±15%

Waste Flow: 2000ml/min (±10%)

1.10.3 Electrical Requirements

Motor 1/3 HP

Voltage 115 V~

Hertz 60

Amps 10

Phase single

Power Cord (length) 8 ft (2.4 m)

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 13 General Information

1.10.4 Membrane Performance Characteristics

Salt rejection (TF Membranes): 95% minimum at initial testing at factory.

Test Solution: Inlet water 1000 PPM NaCl

Conductivity: 2000 micro mhos-cm

Operating Pressure: 200 PSI

Product Back pressure: 0 PSI

1.10.5 Environmental Requirement

Minimum Maximum

Ambient Temperature 4°C (39°F) 32°C (90°F)

Storage Temperature 2°C (36°F) 32°C (90°F)

Altitude N/A 10,000 feet

CAUTION:

This equipment must not be allowed to freeze. Irreparable harm to various

components, including RO membranes may result.

NOTE:

The user/operator should recognize that moisture can be caused by condensation

and is not necessarily an equipment leak. This equipment will function in the

presence of condensation.

1.11 Disposal

Disposal of this product or parts must be carried out according with local disposal

codes.

1.12 Electromagnetic Interference

This equipment can generate, uses and can radiate radio frequency energy and, if not

installed and used in accordance with these instructions, may cause harmful

interference to other devices in the vicinity. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference with other devices, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one

or more of the following measures:

• Reorient or relocate the receiving device

• Increase the separation between the equipment

• Connect the equipment into an outlet on a circuit different from that to

which the other device(s) is connected

• Consult the field service technician or manufacturer for help.

F-801 Internal RO System by GE Osmonics

12552e – 27 Feb 04 1 - 14 General Information

1.13 Service Assistance

If service assistance is required, please take the following steps:

Consult the “Troubleshooting” section of this manual (Chapter Five). If the problem

cannot be identified and corrected by any of the procedures found in that section,

then...

Contact your Facility Equipment Technician. If the technician is unable to help then…

Call GE Osmonics Technical Service Department at (800) 633-3080 or (206) 395-2200.

Technicians are available for all calls between 7:00 a.m. and 4:30 p.m. PST, Monday

through Friday. Technicians are also available at other times for emergency calls

only. Product consultants will be on hand to discuss the problem with you and

endeavor to rectify it over the phone. If the problem appears to be of a more serious

nature, you will be given instructions regarding the action to be taken. Prior to making

the phone call, you must be prepared to answer two questions:

1. What RO do you have, i.e. F-801

2. What is the serial number of your RO? (Label, found on back of Remote

Monitor.)

RO SERIAL NUMBER: ______________________

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

Other documents

-

Gima 33690 Owner's manual

-

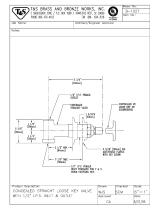

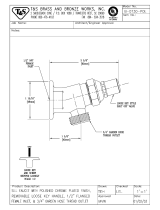

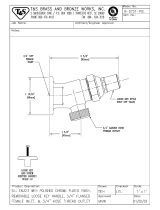

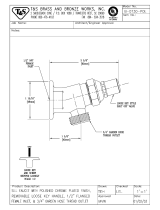

T & S Brass & Bronze Works B-1027 Datasheet

T & S Brass & Bronze Works B-1027 Datasheet

-

Boyel Living BWE-A-96135HORB Installation guide

Boyel Living BWE-A-96135HORB Installation guide

-

Fujifilm XD2000 Operating instructions

-

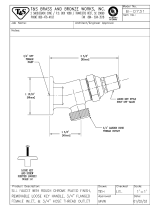

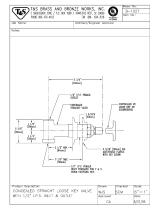

T & S Brass & Bronze Works B-0731 Datasheet

T & S Brass & Bronze Works B-0731 Datasheet

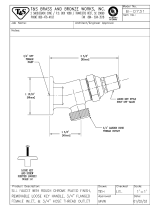

-

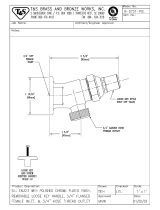

T & S Brass & Bronze Works B-0731-POL Datasheet

T & S Brass & Bronze Works B-0731-POL Datasheet

-

T & S Brass & Bronze Works B-0730-POL Datasheet

T & S Brass & Bronze Works B-0730-POL Datasheet

-

PRO+AQUA PRO-RO-I Operating instructions

PRO+AQUA PRO-RO-I Operating instructions

-

OmniFilter B2000 Installation, Operation and Maintenance Manual

-

US Filter M SERIES - 2000 Operation and Maintenance Manual

US Filter M SERIES - 2000 Operation and Maintenance Manual