The Graco Air Compressor 2.40E 14 is a professional-grade air compressor designed for heavy-duty applications, such as powering Xtreme Sprayer carts. It features a powerful 2.4 horsepower motor that delivers up to 14 CFM at 100 PSI, making it suitable for a wide range of tasks, including spraying, inflating tires, and operating pneumatic tools. The compressor also boasts a durable cast-iron pump and a large 4-gallon tank for extended use. Additionally, it comes equipped with an oil-free design for low maintenance and a built-in thermal overload protector to prevent overheating.

The Graco Air Compressor 2.40E 14 is a professional-grade air compressor designed for heavy-duty applications, such as powering Xtreme Sprayer carts. It features a powerful 2.4 horsepower motor that delivers up to 14 CFM at 100 PSI, making it suitable for a wide range of tasks, including spraying, inflating tires, and operating pneumatic tools. The compressor also boasts a durable cast-iron pump and a large 4-gallon tank for extended use. Additionally, it comes equipped with an oil-free design for low maintenance and a built-in thermal overload protector to prevent overheating.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

Graco Air Compressor 2.40E 14 User manual

- Category

- Paint Sprayer

- Type

- User manual

The Graco Air Compressor 2.40E 14 is a professional-grade air compressor designed for heavy-duty applications, such as powering Xtreme Sprayer carts. It features a powerful 2.4 horsepower motor that delivers up to 14 CFM at 100 PSI, making it suitable for a wide range of tasks, including spraying, inflating tires, and operating pneumatic tools. The compressor also boasts a durable cast-iron pump and a large 4-gallon tank for extended use. Additionally, it comes equipped with an oil-free design for low maintenance and a built-in thermal overload protector to prevent overheating.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

Other documents

-

Husky H4470 Installation guide

-

Husky H4640 Installation guide

-

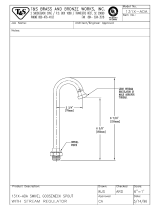

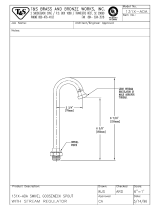

T & S Brass & Bronze Works 131X-ADA Datasheet

T & S Brass & Bronze Works 131X-ADA Datasheet

-

Graco Inc. 238144 User manual

-

Graco Inc. 1100 User manual

-

Graco Inc. 231063 User manual

-

Graco Inc. 207-860 User manual

-

Graco Inc. 237409 User manual

-

Graco Inc. 306926 User manual

-

HP (Hewlett-Packard) 288048 User manual